The expansion and unthinkable development of PCB technology has seen breakthrough products in the market and the LED PCBs is one of them. Nowadays, LED printed circuit boards enable manufacturers to develop and design an array of products that even a decade ago were not in existence. And it has seen massive demand for LED PCBs.

Following the trend, different LED PCB manufacturer has tried their luck in the market. But not all of these LED printed circuit board manufacturers are reliable and may offer you versatile PCBs for LED. So, to make your decision easier we dedicated this write-up to the development, uses, and ways to find the right manufacturer for LED PCBs.

If you need bulk or a few pieces of LED PCBs, but don’t know where to dig in, this article will be the goldmine for you. So, let’s get to it.

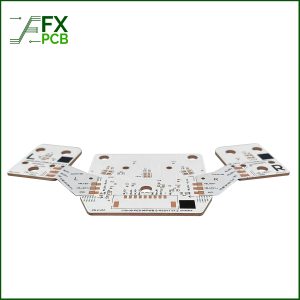

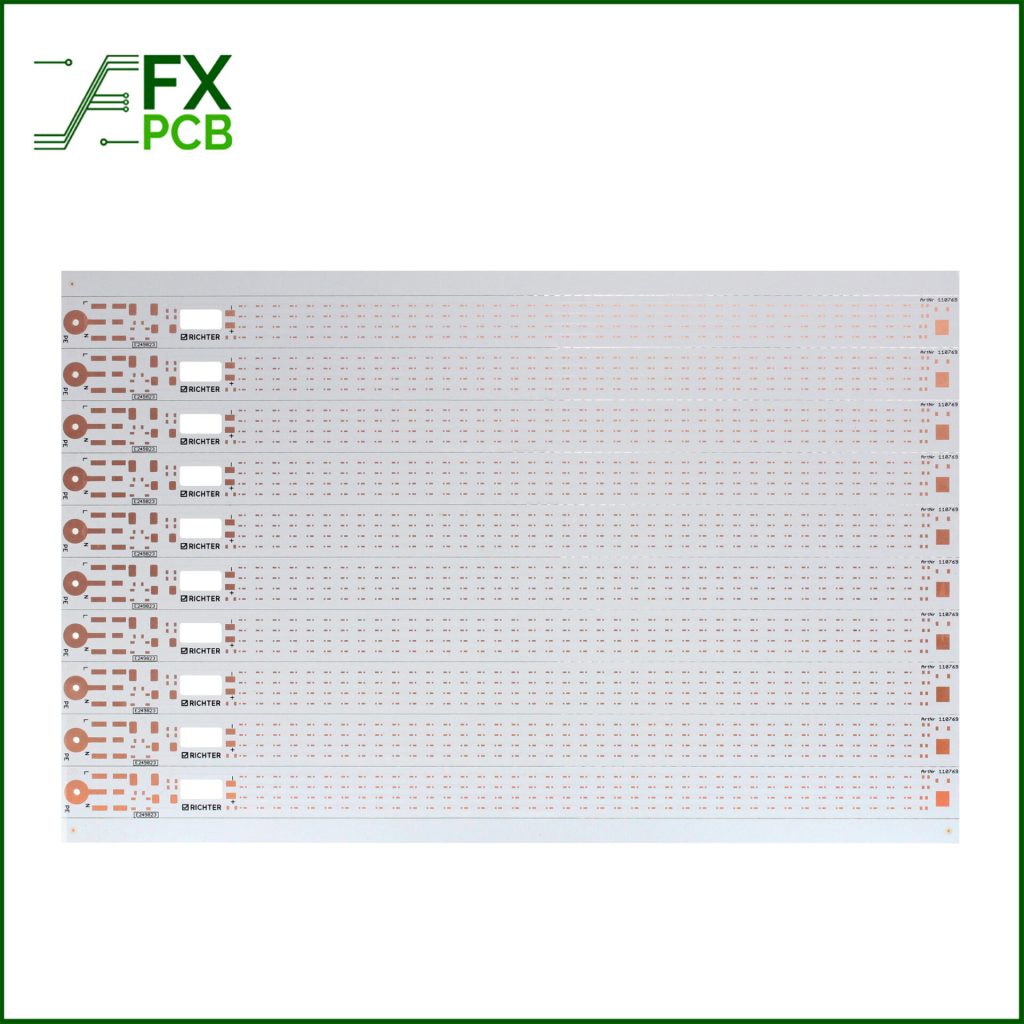

FX PCB is a professional manufacture for the LED PCB. we have Fr4, Aluminum ,Copper base and other materials for customer to choose, and we can give you the best suggestion and solution how to control your cost based on your requirements.

FX PCB uses metal-core circuit boards to produce the LED PCB for its heat conductivity. Also, we will use Aluminum PCB mostly because aluminum has high thermal conductivity. Thus, the dielectric metal easily and comfortably dissipates the extreme heat to keep the LED board cool and efficient.

Tell us your idea or send us your gerber file , we will reply you with the detailed quotation sheet or email.

LED PCB is one of the breakthroughs and latest technologies in the printed circuit board industry. Hence, we must understand the actual meaning of the LED PCB. It will help you know how the LED board works in its real-life application.

So, start with LED that means Light Emitting Diodes. It has semiconductor diodes. When you solder these LEDs on using soldering materials on the printed circuit board, the board will illuminate with the added light. Thus, the LED PCB refers to a printed circuit board with LEDs soldered into it.

But soldering the LED on the PCB isn’t the only importance of this high-tech product. There’re important properties of the board too. Manufacturers usually use a thermal heat sink along with the ceramic base for these circuit board production.

The thermal heat sink works with the ceramic base to reduce the temperature and propels the electric signals to intensify the circuit board efficiency. The heat sink and the ceramic base are attached much like a chip and soldered into the printed circuit board. It connects electrically with the board and passes the light.

The temperature control of the LED PCB is extremely crucial since these boards tend to get overheated in quick time. Thus, manufacturing the LED PCB needs special technology to control the cooling heat capacity and not all manufacturers can handle it. Only a handful of PCB manufacturers such as FX PCB have the right technology to tackle the cooling heat impact of this high-end circuit board.

FX PCB uses metal-core circuit boards to produce the LED PCB for its heat conductivity. Also, we will use Aluminum PCB mostly because aluminum has high thermal conductivity. Thus, the dielectric metal easily and comfortably dissipates the extreme heat to keep the LED board cool and efficient.

When you want to get the best LED PCB manufacturer, you need to dive into the manufacturing process and understand it properly. Otherwise, you will not find the manufacturer properly.

However, you need to look at a few points for the manufacturer of the LED PCB-

Also, you can get hybrid LED PCBs if you need them. You need to clarify the manufacturer to get the hybrid ones in proper conditions. A hybrid LED circuit board has one side made of a standard metal (aluminum) base and the other side has a non-thermal material.

Different types of LED printed circuit boards bring different benefits for the users. The most common advantages may include-

The possible applications of the LED soldered PCBs are overwhelming. It includes-

LED PCB is the latest breakthrough in the circuit board industry. When you get the best LED PCB manufacturer such as FC PCB, your device making will become easier and comfy. Also, our LED PCBs are made using high-end soldering technology to reduce the heat impact. Thus, the LED circuit boards offer durability and lasting performance too. Also, with these versatile applications, these printed circuit boards are the future of the PCB industry.

I am Peter Gong. I have been working in PCB and PCBA industry for 15+ years now. I have been a part of the PCB revolution with my dedication to circuit board technologies and creative ideas. I write in FX PCB to impart my knowledge on PCB and PCBA for all circuit board lovers, manufacturers, and users.

WhatsApp us