Complete Guide to the Manufacturing Process of Ceramic PCB

- Published in Informative

Ceramic PCB: Its Materials, Types, Benefits and Drawbacks

- Published in Ceramic PCB, Informative

Ceramic PCB: A Detailed Material Property Comparison

- Published in Informative

Introduction of the Ceramic PCB Manufacturing Process

- Published in Informative

Designing Ceramic PCBs for Optimal Thermal Management

- Published in Ceramic PCB

CERAMIC PCB: ITS MATERIALS, TYPES, PROS & CONS

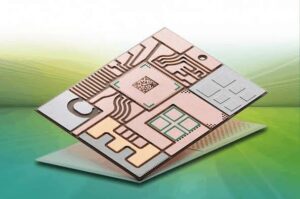

When typical PCB substrate materials are subjected to high pressure or high temperature, failures may occur. Ceramic PCB substrate material, on the other hand, can withstand extremes of temperature, pressure, corrosion, and vibration in electronic circuits. Boards made of ceramic are excellent heat sinks because of their low coefficient of thermal expansion and strong thermal conductivity. These printed circuit boards (PCBs) excel in demanding environments, such as those found in the aerospace and automotive sectors.

In light of this, the purpose of this page is to offer a thorough introduction to ceramic PCBs, including a discussion of their properties, classifications, production technique, and potential uses.

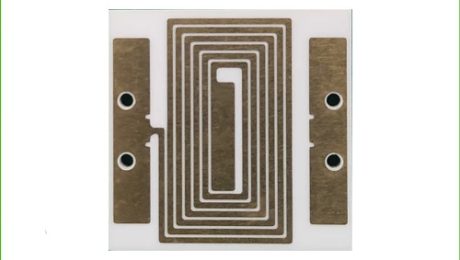

Classifications of Ceramic PCB

High-temperature co-fired Ceramic PCB, low-temperature co-fired ceramic PCB, and thick film ceramic PCB is the three broad categories that may be established according to the processes of ceramic PCB production.

- High-Temperature Co-fired Ceramic (HTCC) PCB

- Low-Temperature Co-fired Ceramic (LTCC) PCB

- Thick Film Ceramic PCB

MATERIAL USED IN CERAMIC PCB

Common ceramic materials used in PCB production are as follows:

Al2O3 (Alumina) –

Concerning mechanical strength, chemical stability, thermal conductivity, and electrical characteristics, Al2O3 outshines other oxide ceramics. Alumina is the most popular choice for ceramic substrates since it is easily accessible as a raw material. Sensor circuits, shock absorbers, and engines all benefit from the usage of ceramic printed circuit boards made from Al2O3. Al2O3 ceramic Boards increase the performance and thermal efficiency of automotive circuits because of their strong thermal stability.

Aln, Or Aluminum Nitride,

Substrate material AlN is notable in the PCB sector due to its strong thermal conductivity and coefficient of expansion. AlN has a thermal conductivity between 170 W/mK and 220 W/mK. This is because the coefficient of thermal expansion (CTE) of AlN ceramic is similar to that of silicon semiconductor chips, resulting in a strong bond and a dependable assembly. AIN is employed in automotive sensor circuits because of its ability to endure high heat, corrosion, and vibration while still producing highly precise and sensitive sensor outputs.

Oxide Of Beryllium (Beo)

Ceramic PCB substrates made from BeO have a heat conductivity of around nine times that of Al2O3 and are higher than aluminium. Although AlN is more chemically stable, Al2O3e has higher electrical isolation, and BeO has both. For air or liquid cooling, BeO is employed in situations where the PCB is exposed to high temperatures or in high-density PCBs with limited space.

Properties of Ceramic PCB

Ceramic printed circuit boards (PCBs) have many advantages over their typical glass fibre epoxy, polyimide, polystyrene, and phenolic resin counterparts.

- Top-notch thermal conductivity

- Safe against the effects of chemical erosion

- An acceptable level of mechanical vigour

- Consistent with the CTE requirements of materials

- High-density tracing that is simple to implement.

ADVANTAGES OF CERAMIC PCBS

Superior Heat Transfer Properties

The values vary from around 25 to about 330 W/(m•K) depending on the material employed (alumina to beryllium, as mentioned above). Almost 20 times that of FR4 PCB. Ceramic’s superior performance and resistance to heat make it ideal for protecting electronic components from overheating.

Reduced Thermal Expansion (CTE)

It is hard, stable, and consistent even when temperatures rise and fall because of its exceptional interatomic connections.

Outstanding Heat Insulation

When used as a substrate for a circuit board, ceramic’s high insulating properties will reduce the likelihood that heat will transfer through it, protecting its electronic components.

Non-living, or inorganic

Inorganic components provide continued functionality and service life. The material’s resistance to chemical erosion is also noteworthy.

Layering, or Many

When it comes to complex tasks, a multi-layer ceramic PCB is a way to go. The durability of the material allows for an additional layer to be placed while still ensuring the security of the underlying parts. It performs well in demanding settings.

Supersonic

A ceramic PCB’s dimensional and thermal stability allows it to tolerate high frequencies. The medical and aerospace industries, which depend a lot on the reliable transmission of high-frequency data and electrical signals, will benefit from this.

Disadvantages of Ceramic PCBs

Modification

Due to their potential fragility, ceramics need extra care and careful treatment during assembly and testing.

Value for money

The cost of ceramic is rather low. Overall, though, the cost is more than it would be with more conventional materials for a circuit board. With the specialized machinery required for its manufacture, the price tends to be higher.

PCB MANUFACTURER IN CHINA

FX PCB:

With over a decade of expertise, FX PCB Co., Ltd has become a reliable PCB and PCBA Supplier. More than a hundred of their current clients can attest to their global reach in printed circuit board manufacturing. These are mostly long-term partners with whom we work closely. We take great pride in the fact that our customers rate us at or above 99% satisfied with our service, quality, and pricing.

MOKO Technology:

MOKO was founded in 2006 and since then has served clients from over 100 different countries, providing them with comprehensive PCB solutions .

All PCB:

In 2015, ALLPCB opened its doors in Hangzhou, China, to provide its services in component sourcing design and fabrication. Fast and reliable electronic manufacturing services are provided to clients in more than 160 countries thanks to in-house designed online technologies and joint production facilities.

PCBWay

PCBWay has been in the PCB industry for over 10 years, and in that time they’ve built a solid reputation for providing reliable products and first-rate service to clients across a variety of sectors

Ceramic PCB

HiTech Circuits:

Hitech was founded in 1997 and has since been China’s preeminent PCB supplier. They provide their clients with a wide range of services, such as components sourcing, PCB fabrication, PCB assembly, order tracking, and quality control monitoring. benefits from an established supply chain, expert engineers, cutting-edge machinery, and stringent quality assurance measures.

JLC PCB:

Since its founding in 2006, JLCPCB has been a prominent PCB supplier in China because of its dedication to innovation and improvement. They can provide clients with PCBs that are both reliable and affordable and can be turned around in a relatively short amount of time.

China PCB One:

ChinaPCBOne was started in 2008 to be a one-stop shop for electronic prototypes and mass production orders. The China PCB One plant in Shenzhen is in a good location that lets the company meet the needs of customers all over the world.

- Published in Ceramic PCB