As an integral part of the electronics industry, we at FX PCB understand the critical role that printed circuit boards (PCBs) play in ensuring the reliability and performance of electronic devices. Among the various types of PCBs available, thick PCB boards have emerged as a preferred choice for many applications due to their unique characteristics and benefits. Let’s examine the significance of thick PCB boards in our manufacturing processes at FX PCB.

Exploring Thick PCB Boards

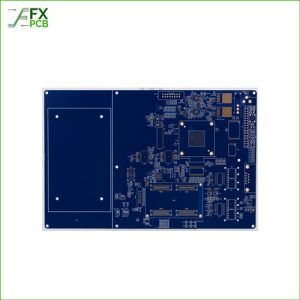

Thick PCB boards, also known as heavy copper PCBs or thick copper PCBs, are characterized by their increased copper thickness compared to standard PCBs. While standard PCBs typically have copper thickness ranging from 1oz to 3oz, thick PCB boards feature copper thickness exceeding 3oz, often reaching up to 20oz or more. This substantial copper thickness provides several advantages that make thick PCB boards ideal for demanding applications.

- Enhanced Durability and Reliability

One of the primary advantages of thick PCB boards is their enhanced durability and reliability. The thicker copper layers offer greater mechanical strength, allowing the PCB to withstand harsh environmental conditions, vibrations, and mechanical stress. This durability ensures long-term performance and reliability, making thick PCB boards suitable for applications where reliability is paramount, such as aerospace, automotive, and industrial electronics.

- Improved Thermal Management

Thermal management is critical in electronic design, especially for high-power applications. Thick PCB boards excel in dissipating heat due to their increased copper thickness. The higher thermal conductivity of copper allows for efficient heat dissipation, preventing overheating and ensuring the optimal functioning of electronic components. This capability is particularly beneficial for power electronics, LED lighting systems, and other applications that generate significant heat.

- Enhanced Current Carrying Capacity

Thick PCB boards offer superior current carrying capacity compared to standard PCBs. The increased copper thickness reduces resistance, allowing for higher current densities without risking overheating or voltage drops. This capability is essential for power electronics, motor drives, and other high-current applications where maintaining stable electrical performance is crucial.

- High-Frequency Performance

In addition to their mechanical and thermal advantages, thick PCB boards exhibit excellent high-frequency performance. The enhanced copper thickness minimizes signal loss and impedance mismatch, enabling reliable signal transmission at high frequencies. This makes thick PCB boards suitable for high-speed digital circuits, RF/microwave applications, and telecommunications systems where signal integrity is paramount.

Applications of Thick PCB Boards

The unique characteristics of thick PCB boards make them well-suited for various applications across various industries. At FX PCB, we leverage the capabilities of thick PCB boards to meet the demanding requirements of our customers in sectors such as:

- Automotive Electronics: The automotive industry relies on thick PCB boards for critical systems such as engine control units (ECUs), powertrain control modules (PCMs), and advanced driver-assistance systems (ADAS), where reliability and durability are paramount.

- Industrial Automation: Thick PCB boards play a crucial role in industrial automation equipment, including motor drives, PLCs, and control systems, where high reliability and robust performance are essential for uninterrupted operation.

- Renewable Energy: In renewable energy systems like solar inverters and wind turbine controls, thick PCB boards offer the reliability and thermal management capabilities necessary to ensure efficient energy conversion and grid integration.

- Medical Devices: Thick PCB boards are utilized in various medical devices, including diagnostic equipment, patient monitoring systems, and implantable devices. Its durability, reliability, and ability to withstand sterilization processes make it suitable for critical medical applications, where precision and reliability are paramount.

Empowering Innovation Through Our Advanced Thick PCB Solutions!

At FX PCB, we recognize the significance of thick PCB boards in meeting the evolving demands of modern electronic applications. From their enhanced durability and reliability to their superior thermal management and high-frequency performance, thick PCB boards offer a solid foundation for building reliable, high-performance electronic devices. By leveraging our expertise in thick PCB manufacturing, we continue to deliver innovative solutions that enable our customers to excel in their relevant industries.

Contact us today to learn more about our thick PCB capabilities and how we can support your next project!