Description

High-Performance Copper Coin PCB: The Ultimate Thermal Management Guide

A copper Coin PCB is embedding or inserting a copper block into a specific area of a PCB, and it can also be called an embedded copper coin PCB. Heat-generating electronic components are directly mounted onto the copper block, which utilizes the high thermal conductivity of copper to dissipate heat quickly. Embedded copper coin PCBs not only offer excellent heat dissipation but also save board space, making them increasingly popular in recent years.

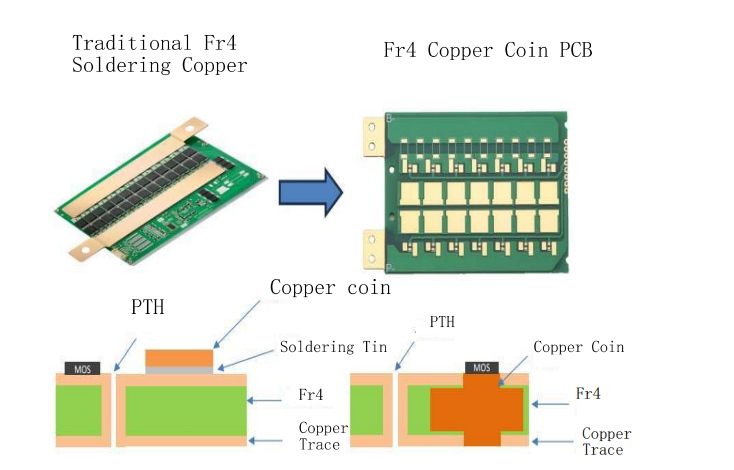

Copper Coin PCB vs. Traditional FR4 with copper

Traditional methods of attaching copper or heatsinks to FR4 boards typically involve thermal interfaces and the Surface Mount Technology (SMT) process. While cost-effective, this approach introduces thermal resistance and complexity.

The FX PCB Advantage: By inserting the copper coin directly into the PCB structure, the Embedded Copper Coin method creates a near-direct heat path. This drastically improves current handling, ensures stable junction temperatures, and allows the component to stand higher power loads than standard SMT assembly alone.

Production Process of Embedded Copper Coin PCB

The production process for embedded copper coin PCBs is more complex than standard PCBs due to the inherent challenge of managing the differences in Thermal Expansion Coefficients (CTE) between the copper coin and the PCB base material (e.g., FR4, High-Tg).

Our proprietary lamination process is precisely controlled to overcome common issues like depressions, resin overflow, and cracks between the copper coin and the resin.

Copper Coin PCB Fabrication Process Summary:

Inner Layer Fabrication: Circuit patterning and etching.

Precision Routing: Milling a precise slot or cavity for the copper coin insertion.

Coin Insertion & Cleaning: Critical steps to ensure a contaminant-free bonding surface.

Metallization & Plating: Ensures electrical and thermal connection to the surrounding layers.

High-Pressure Lamination: A multi-stage cycle that bonds the layers and securely embeds the coin while controlling resin flow.

Outer Layer Fabrication: Final patterning, drilling, and finishing.

Copper Coin PCB Inner Layer Fabrication

Copper Coin PCB Outer Layer Fabrication

This comprehensive process ensures the high performance and reliability of the final product, suitable for demanding applications like 5G communication equipment and power modules.

Frequently Asked Questions (FAQ)

Q1: What are the main types of Copper Coin PCB designs?

A: There are three primary types:

- Embedded (Buried) Coin: The coin is integrated during the lamination process and can be flush with both sides.

- Press-fit Coin: The coin is pressed into a finished PCB cavity, offering cost-effective local cooling.

- T-Shape/U-Shape Coin: These shapes allow for more surface area on internal layers to spread heat while maintaining a small footprint on the component layer.

Q2: When should I choose a Copper Coin PCB over a Metal Core PCB?

A: Choose Copper Coin when you need a multilayer design with high-density routing on both sides, but only have specific “hot spots” (like a power amplifier) that require extreme cooling. MCPCBs are better suited for simple, single-layer high-power LED arrays.

Q3: Does the copper coin affect the PCB’s signal integrity?

A: When designed correctly, no. However, since the coin is a large conductive mass, it must be accounted for in the layout to maintain proper clearance from high-speed signal traces to avoid parasitic capacitance.

Q4: What surface finishes are best for Copper Coin PCBs?

A: ENIG (Electroless Nickel Immersion Gold) and OSP (Organic Solderability Preservative) are the most common. ENIG is preferred for its excellent solderability and flat surface on the coin.

Partner with FX PCB: Solve Your Thermal Challenges Today

As electronic products trend toward being lighter, thinner, and smaller, addressing heat dissipation challenges has become increasingly urgent. Embedded copper coin PCBs offer an effective, space-saving solution.

If you are looking for a reliable PCB manufacturer to produce your Copper Coin PCB design, send us your inquiry to FX PCB to get a quote!