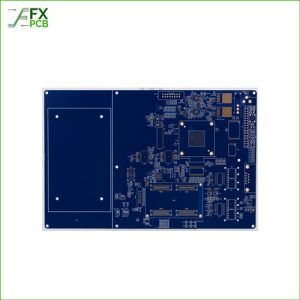

As a leading provider of flexible printed circuit boards (PCBs), we at FX PCB understand the critical role these components play in modern electronics. With the ever-increasing demand for smaller, lighter, and more versatile electronic devices, flex PCBs have become essential in various industries, from consumer electronics to medical devices and aerospace applications.

Let’s explore the advantages of choosing a specialized flex PCB manufacturer like ours for your next project.

Expertise in Flex PCB Manufacturing

At FX PCB, flex PCBs are not just a part of what we do; they are our specialty. Our team of engineers and technicians has extensive experience and expertise in designing, fabricating, and assembling flex PCBs. Unlike traditional rigid PCBs, flex PCBs require specialized techniques and materials to ensure optimal flexibility, reliability, and performance.

By partnering with a specialized flex PCB manufacturer, you can leverage our knowledge and capabilities to develop custom solutions that meet your specific requirements. Whether you need a simple single-layer flex PCB or a complex multi-layer design, we have the expertise to deliver high-quality, cost-effective solutions tailored to your application.

Advanced Manufacturing Technologies

Innovation is essential to staying ahead of the competition in today’s quick-paced electronics sector. At FX PCB, we invest in advanced manufacturing technologies to ensure our customers receive the highest quality flex PCBs. From precision laser cutting and drilling to automated assembly processes, we utilize state-of-the-art equipment and techniques to deliver superior results.

Our commitment to innovation extends beyond our manufacturing processes. We continually research and develop new materials and techniques to improve the performance and reliability of our flex PCBs. By partnering with us, you can take advantage of the latest advancements in flex PCB technology to enhance the functionality and durability of your products.

Customized Solutions for Every Application

One of the key advantages of choosing a specialized flex PCB manufacturer is the ability to access customized solutions tailored to your specific application. At FX PCB, we understand that every project is unique, with its own set of requirements and challenges. That’s why we offer a comprehensive range of customization options to meet your exact specifications.

Whether you need a flexible PCB with high-temperature resistance for automotive applications or a thin, lightweight design for wearable devices, we can work with you to develop a solution that meets your needs. Our team of experts will collaborate with you throughout the design and manufacturing process to ensure that your flex PCBs perform optimally in your application.

Reliable Supply Chain Partnerships

The global economy of today makes supply chain management more crucial than ever. As a specialized flex PCB manufacturer, we have established strong partnerships with leading raw materials and components suppliers. This enables us to source high-quality materials at competitive prices and maintain a reliable supply chain to meet our customers’ needs.

By partnering with FX PCB, you can benefit from our extensive network of suppliers and our commitment to quality and reliability. Whether you need a small prototype run or a large-scale production run, you can count on us to deliver your flex PCBs on time and on budget.

Experience the Flexibility of Innovation with Us Today!

Choosing a specialized flex PCB manufacturer like FX PCB offers numerous advantages for your next project. From our expertise in flex PCB manufacturing to our advanced technologies and customized solutions, we are committed to delivering high-quality, reliable flex PCBs that meet your specific requirements.

Reach out to us today to learn more about how we can help you achieve your goals with flexible design solutions!