Description

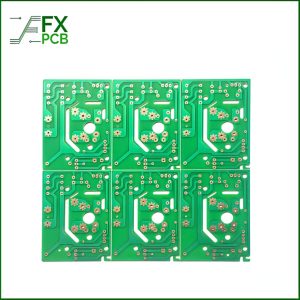

What is 94V 0 Circuit Board?

94V-0 circuit boards are a kind of printed circuit board (PCB) with flame-retardant properties, meaning they don’t catch fire easily. This kind of PCB is primarily used in products that require high levels of safety such as computers, cars, and medical equipment. They can also be used in other applications such as toys, watches, and more.

In this guide, we’ll take a visual look at 94 V-0 circuit board construction. We will provide you with all the details you need to know about this type of board. Hence, you’ll learn everything about 94 V-0 circuit boards here.

It includes the from components that make up a 94 V-0 board. Also, you will know how to identify it from other types of boards. Irrespective of your electronics or engineering projects you do, having a good understanding of 94 V-0 boards is essential for success. So, let’s get started!

Overview of 94 V-0 Circuit Boards

You may have heard about 94 V-0 circuit boards. However, do you know what they are and why they’re important? In this guide, we’ll explain the basics of 94 V-0 circuit boards first. A 94 V-0 circuit board is a nonflammable printed electrical board.

It is mainly designed to provide insulation for the components in the harshest conditions. It is composed of nonflammable material, usually epoxy glass. This means it won’t ignite in the presence of higher temperatures or open flames. The nonflammable feature makes it the ideal choice for equipment that runs at a high voltage. When the devices have constant exposure to extreme temperatures, 94 V-0 circuit boards are handy.

The number 94 indicates that it is UL-certified. Hence, it can withstand a maximum temperature of 140 degrees Celsius. Also, its V-0 rating indicates its UL flammability rating. It shows the time needed to catch fire and the time needed for the fire to be extinguished once ignited. As the rating suggests, 94 V-0 circuit boards are nonflammable, almost. It won’t catch fire quickly and so, ideal for continuous harsh applications. Therefore, you will see its applications in the military, aerospace, etc.

Why Use 94V-O Circuit Boards?

There are plenty of reasons why you might choose to use 94V-0 circuit boards. Some of the most common benefits include:

- High levels of reliability: These circuit boards have been tested to meet UL94 V-0 standards. Hence, they have no combustible particles. You can trust that they won’t fail or cause a fire hazard.

- Low cost: The cost of producing these types of circuit boards is relatively low compared with other circuits. It happens due to their flame-retardant properties and simple design. We even offer more affordability.

- Versatility: These boards are very versatile. So, they can be used in a wide range of applications where safety is a factor. It includes medical equipment to industrial machines.

The 94V-0 circuit board is an incredibly versatile component. The 94 V0 PCBs can be used in different scenarios where fire safety is a priority. With its low cost, reliable performance and easy integration into existing products, it’s no wonder that this type of PCB is so popular among makers and engineers alike.

Considerations When Purchasing 94 v-0 Circuit Boards

When you’re ready to purchase a 94 v-0 circuit board, there are a few key things to consider. Only then, you can get the best 94 V-0 circuit boards.

PCB size:

First, size is one of the most important factors. You’ll need to measure your application and then target the appropriate board size for success. Thankfully, at SFX PCB, you can get custom-made 94 V-0 circuit boards for your necessity. We can quickly make and transport the 94-V0 circuit boards with different sizes for your device requirement.

A number of layers:

Beyond size, you’ll want to determine the number of layers that best meets your needs. It is important because you get 94 V-0 circuit boards in single, double and multi-layer design. You should also consider the desired finished thickness. Depending on your applications, these 94 V-0 PCBs can be made in 0.5mm~4.5mm thickness.

Additionally, it’s important to ensure that your design adheres closely to IPC standards. It will provide a valuable set of guidelines and requirements for quality in these circuit boards.

Material and construction quality:

Finally, don’t forget that your choice of material impacts the performance and longevity of the circuit board. 94 v-0 materials are flame retardant and self-extinguishing. Hence, these features will make them ideal for certain applications. Nonetheless, for the best nonflammable functions, check the material and its quality.

Types of 94 V-0 Circuit Boards

You’re probably wondering about different types of 04 V-0 circuit boards. The good news is that the V-0 rating covers a range of printed circuit board types and materials. Thus, you can quickly find the right board for your project.

Let’s break down some of the most popular varieties you can get for 94 V-0 rating. We currently work with these 94 V-0 PCBs.

Single Layer Boards

Single-layer boards are ideal for simple electronic projects with low to medium complexity. They are easy to understand and manufacture. Hence, 94 V-0 single-layer PCBs are often used by beginners and hobbyists. With these boards, all of the electrical components are on one side (the top) of the circuit board. The bottom side has nothing more than a few mounting holes for attaching it to a base plate. For the flammability rating, single-layer PCBs use different construction and engineering techniques.

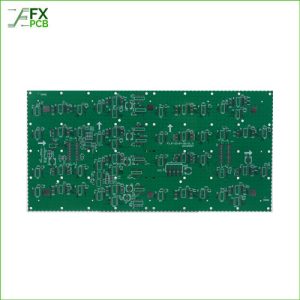

Double Layer Boards

Double-layer boards include electrical components and connection paths on both sides. The printed circuit board has more room for components for use on both sides. Hence, the 94 V-0 PCBs with double layers are ideal for more complex circuitry.

First, they provide more room for layers of components. Secondly, they are helpful in outlining precisely where current should flow from one side to another.

Multilayer Boards

Multilayer boards offer even more versatility and complexity than double-layer boards. They do so due to their ability to hold multiple electrical layers. You will see multilayer They allow densely packed circuits. It is ideal for modern electronic systems that require advanced design capabilities or higher current carrying capacity.

These boards help minimize interference between circuits. It does so as each connection is enclosed within its own layer in the stack-up structure.

Uses and Applications for 94 v-O Circuit Boards

When it comes to 94 V-0 circuit boards, you really can do just about anything. Their performance, stability, and usability make them ideal for a wide range of applications. It ranges from custom recreations of vintage audio equipment to high-powered industrial power supplies.

Here are some uses and applications for 94 V-O circuit boards:

Home Electronics

94 V-0 circuit boards can be used in home electronics, such as amplifiers and radios. First, these boards provide excellent insulation. Moreover, they have a better impact resistance than other types of boards. It makes them ideal for high-performance audio and home automation systems.

Also, their high resistance against heat allows the PCBs to remain functional for hours. Thus, users can play their audio devices continuously and enjoy supremacy.

Industrial Applications

94 V-0 circuit boards are often the go-to choices for demanding applications, like industrial power supplies. They work well in circuits subjected to high voltage or current loads. It can help protect sensitive components from damage caused by thermal shocks.

Therefore, it is preferable in industrial jobs with high-demanding applications. We provide you with high-quality 94-V0 PCBs for industrial applications.

Automotive Electronics

The superior heat resistance of 94 V-O circuit boards makes them an excellent choice for automotive electronics applications. You will find its uses in climate control systems, engine control units, and telematics systems.

This means people can enjoy increased reliability when using these devices in their car or truck. So, you should consider getting the 94 V0 circuit boards if you are in the automotive industry.

How to Solder Components to a 94 v-O Circuit Board

You must solder components to your 94 v-O circuit board to create a strong connection. Also, it is needed to complete your circuit. Although the process may appear complex, you will find it easier with our suggestions.

Materials Needed:

- Soldering iron

- Rosin core solder

- Flux

- Cotton swabs or brushes

- Isopropyl alcohol or flux remover

Now that you have all the materials you’ll need, let’s get started!

Prepare the components:

You must begin by preparing the components and the circuit board. Make sure that all pins are straight and none of them have bent out of shape. If they have, use needle nose pliers to straighten them out.

Clean the materials and pins:

Then you should clean the area where you are soldering. For this, use a cotton swab or brush dipped in flux or isopropyl alcohol. You must ensure there’s no dust or dirt on it. Once the components and board are prepared, apply rosin core solder directly onto the pins.

It should be on both components and the circuit board pads. Remember that too much solder makes it difficult for you to remove components later on.

Start soldering the circuit board:

Next, heat one soldering point with your soldering iron until the solder melts and flows onto the component pins and pads, making sure it covers both securely. Repeat for all of your other components as needed before allowing your board to cool down completely. Once it cools down, use a cotton swab to remove any residue from your soldering project before testing it out!

Troubleshooting and Maintenance for 94 v-0 Circuit Boards

Sometimes, troubleshooting and maintenance of 94 V-0 circuit boards will be necessary. There are a few things you should keep in mind for it. Regular maintenance and inspections are important for keeping these circuit boards functioning correctly.

Here are some steps for maintaining and troubleshooting 94 V-0 circuit boards:

Regular inspection:

Regularly check the board for any signs of damage. There can be cracks, bulges, discoloration, or other irregularities. You should pay attention to the solder joints too. When they’re dirty or corroded, you may need to replace them.

Look for shorts:

Short circuits can cause the board to overheat and become damaged. Thus, be sure to look for any short tracks or components on the board. Or it could lead to a circuit malfunction.

Check connections:

Check that all components are securely connected to the board to prevent electrical problems. You should ensure that each component is securely seated into its PCB pocket. Finally, be aware of the loose screws on the board that could create electrical issues.

Clean it Up:

Clean your circuit boards with a damp cloth using non-abrasive detergents, before use. Plus, when necessary, remove any dust or dirt buildup from their surfaces. It allows the 94 V0 circuit boards to function in harsh conditions. It will help keep them in tip-top shape so they continue running smoothly over time.

Review wiring diagrams:

Before attempting any repairs or updates on your board, review the wiring diagrams. It helps you know all components connected to it. Thus, you know what’s going on. As a result, you can make informed decisions about updates or repairs that need to be made.

Conclusion

All in all, 94 V-0 Circuit Boards are important components of many types of electronics. From their special UL flame retardant rating to their similarities to other boards, these PCBs are superb. Henceforth, you will find them ideal for the harshest jobs.

And you can always contact SFX PCB to manufacture 94 V0 circuit boards for you. We offer affordable, high-quality, reliable, and demanding 94 V0 PCBs. Also, we provide you with 24X7 services and fast delivery. Hence, you should find our 94 V0 printed circuit boards ideal for your business.