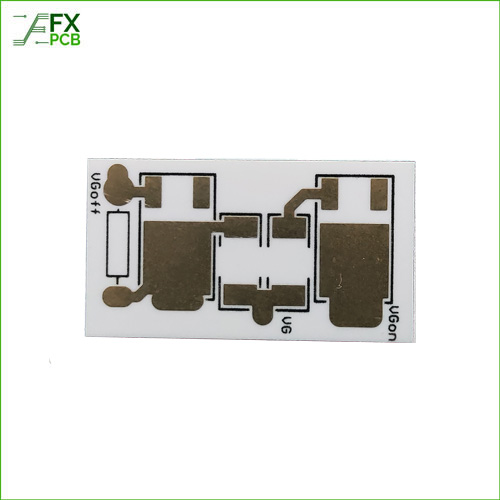

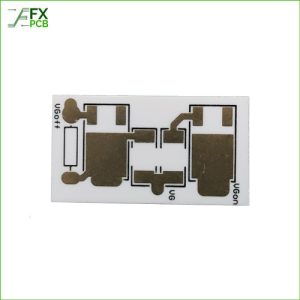

Description

What is the Ceramic PCB Substrate?

FX PCB listed two kinds of Ceramic PCBs, which are Aluminum Nitride Ceramic PCB and Alumina Ceramic PCB (ALN and AI203) Properties for your reference:

BECAUSE OF ITS HIGH THERMAL CONDUCTIVITY, LOW ROUGHNESS, AND EXPANSION, Aluminum PCB (AI203) is the most popular ceramic material for Ceramic PCB. Meanwhile, the price is cheaper than the ALN and Beo.

Alumina Ceramic PCB Materials datasheet:

| Item | Unit | Value | Test Standard |

|---|---|---|---|

| Color | / | White | 3.2 |

| Density | g/cm³ | ≥ 3.7 | GB/T 2413 |

| Thermal Conductivity | 20℃, W/(m • K) | ≥ 24 | GB/T 5598 |

| Dielectric Constant | 1MHz | 9~10 | GB/T 5594.4 |

| Dielectric Strength | KV/mm | ≥ 17 | GB/T 5593 |

| Flexural Strength | Mpa | ≥ 350 | GB/T 5593 |

| Camber | Length‰ | ≤ 2‰ | |

| Surface Roughness Ra | μ m | 0.2~0.75 | GB/T 6062 |

| Water Absorption | % | 0 | GB/T 3299-1996 |

| Volume Resistivity | 20℃, Ω .cm | ≥ 10¹⁴ | GB/T 5594.5 |

| Thermal Expansion | 10⁻⁶ mm 20~300℃ | 6.5~7.5 | GB/T 5593 |

Even though the ALN PCB will be more expensive than the AI203, ALN has high conductivity, and the expansion coefficient matches Si, which makes the customers still choose it as the material for their products, here you can see the details for the ALN material properties

Alumina Nitride Ceramic PCB Datasheet:

| Item | Unit | Value | Test Standard |

|---|---|---|---|

| Color | / | Gray | 3.2 |

| Density | g/cm³ | ≥ 3.33 | GB/T 2413 |

| Thermal Conductivity | 20℃, W/(m • K) | ≥ 170 | GB/T 5598 |

| Dielectric Constant | 1MHz | 8~10 | GB/T 5594.4 |

| Dielectric Strength | KV/mm | ≥ 17 | GB/T 5593 |

| Flexural Strength | Mpa | ≥ 450 | GB/T 5593 |

| Camber | Length‰ | ≤ 2‰ | |

| Surface Roughness Ra | μ m | 0.3~0.6 | GB/T 6062 |

| Water Absorption | % | 0 | GB/T 3299-1996 |

| Volume Resistivity | 20℃, Ω .cm | ≥ 10¹³ | GB/T 5594.5 |

| Thermal Expansion | 10⁻⁶ mm 20~300℃ | 2~3 | GB/T 5593 |

The Technology for The Ceramic Circuit Board

There are four kinds of technologies: LTCC (Low-temperature Co-fired Ceramic), HTCC (High-temperature Co-fired Ceramic), DBC (Direct Bonded Copper), and DPC (Direct Plate Copper). It is the thick film technology for LTCC and HTCC, and it will have the problem of poor thermal conductivity, bad precision of the trace, and a surface that is not smooth. If you want to know more details about this technology, you can read here

DBC and DPC have high thermal conductivity, as the copper foil is bonded or plated to the ceramic directly without any middle layer, However, DBC will have the problem of the microbubbles between the ceramic substrate and copper. FX PCB is using the DPC technology for all of our orders. Click here to get more Ceramic technology from us

What’s the FX PCB Ceramic PCB capability?

As a Ceramic PCB Supplier in China, we can support our customers from prototype to mass production. we are not only focusing on single-layer boards but also Multilayer circuit boards.

| Specification | Value |

|---|---|

| Board Thickness (mm) | 0.25/0.38/0.5/0.635/1.0/1.5/2.0/2.5/3.0mm |

| Layer Number | 1-2L |

| Base Copper Thickness (µm) | 18-300µm (0.5-8.5oz) |

| Min Track Width/Space (mm) | 0.075mm |

| Min Hole Size | 0.06mm (PTH) |

| Finished Hole Tolerance (mm) | 0.05mm (NPTH) |

| Outline Tolerance (mm) | 0.05mm |

| Hole Tolerance | ±0.05mm |

| Min Space from Track to Board Edge | 0.2mm |

| Finished Board Thickness |

(0.25-0.38mm) ±0.03mm (0.38-0.635mm) ±0.04mm (0.76-2mm) ±0.05mm |

| Surface Treatment | ENIG, ENEPIG, Immersion Silver |

| Material | ALN, AI203 |

FX Ceramic PCB Manufacturing Process

IQC(incoming material check), Laser Drill, PVD, Plating, Pattern, Etching, QC 1, Soldermask, Silkscreen, Surface treatment, Test, CNC by laser, FQC, Package, Shipping

Ceramic PCB VS Fr4 Material

- Better thermal expansion

- Stronger and lower resistance metal film

- Good solderability of the substrate and high operating temperature 5, Good insulation, and Low High-frequency loss

- High-density assembly possible

- It has a long life and high reliability in aerospace as it does not contain organic ingredients and is resistant to cosmic rays

What kind of fields that the Ceramic PCB can be used in?

The ceramic circuit board is primarily used in the LED field, high-power semiconductor modules, semiconductor coolers, electronic heaters, power control circuits, power hybrid circuits, components, high-frequency switching power supplies, automotive electronics, communications, aerospace, and military electronic components

What kind of PCB files can FX PCB accept?

Gerber file, Cam, Eagle file, CAD, Protel99, 99se, DXP

If you are looking for a Ceramic PCB Manufacturer in China, please contact us by email now!