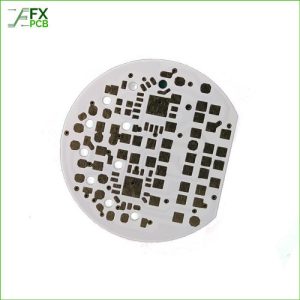

Description

Ceramic PCB AIO203 Capability:

| Board Thickness(mm) | 0.25/0.38/0.5/0.635/1.0/1.5/2.0/2.5/3.0mm |

| Layer Number | 1-2L |

| Base copper thickness(um) | 18-300um(0.5-8.5oz) |

| Min Track width/space(mm) | 0.075mm |

| Min hole size | 0.06mm(PTH) |

| Finished hole tolerance(mm) | 0.05mm(NPTH) |

| Outline Tolerance(mm) | 0.05mm |

| Hole Tolerance | +/-0.05mm |

| Min space from track to board edge | 0.2mm |

| Finished board thickness | (0.25-0.38mm)+/-0.03mm |

| (0.38-0.635)+/-0.04mm | |

| (0.76-2mm)+/-0.05mm | |

| Surface Treatment | ENIG,ENEPIG,Immersion Silver |

| Material | AIN, AI203 |

Ceramic PCB AIO203 Materials Properties:

| Item | Unit | Value | Test Standard |

| Color | / | White | 3.2 |

| Density | g/cm³ | ≥ 3.7 | GB/T 2413 |

| Thermal Conductivity | 20℃, W/(m · K) | ≥ 24 | GB/T 5598 |

| Dielectric Constant | 1MHz | 9~10 | GB/T 5594.4 |

| Dielectric Strength | KV/mm | ≥ 17 | GB/T 5593 |

| Flexural Strength | Mpa | ≥ 350 | GB/T 5593 |

| Camber | Length‰ | ≤2‰ | |

| Surface Roughness Ra | µ m | 0.2~0.75 | GB/T 6062 |

| Water Absorption | % | 0 | GB/T 3299—1996 |

| Volume Resistivity | 20℃, Ω .cm | ≥ 1014 | GB/T 5594.5 |

| Thermal Expansion | 10-6 mm 20~300℃ | 6.5~7.5 | GB/T 5593 |