Description

What is a Multilayer PCB?

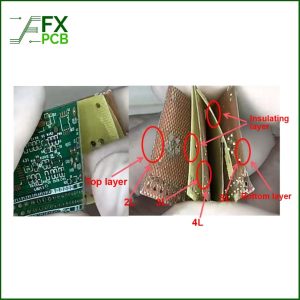

Firstly, a Multilayer PCB normally consists of at least three or more conductive layers, using the combination of inner layer and outer layer. The inner layers are generally used for traces, while the outer layers can place components and signal connections. This can not only ensure the circuit density, but also decrease the electromagnetic interference and signal crosstalk.

How Multilayer PCBs Improve High-Speed Circuit Performance

Although the PCB designer will have enough space to arrange more components and traces, they still need to consider the signal integrity, power integrity, and electromagnetic compatibility. The proper layout and routing can ensure the accuracy and reliability of data transmission. Meanwhile, Thermal management is also important during the design to protect the hot spots and ensure the components operate within a safe temperature.

To meet the layer stacking, the Multilayer PCB manufacturing process is more complex. It includes layer stacking, drilling, metallization, etching, and other steps. This lamination process can meet the required electrical performance, such as reducing the resistance and inductance, and improving the high-frequency signal transmission.

Furthermore, Multilayer PCBs can be designed with different layers; The most popular ones are four layers, six layers, eight layers and etc, to meet various product requirements. Increasing the layer numbers can provide more signal channels and electrical performance, and it can make them ideal for high-speed digital circuits and complex RF applications.

Multilayer PCB applications and Advantages.

Multilayer circuit boards are widely used in telecommunications, medical devices, industrial control systems, automotive electronics, and other various industries.

In communication equipment, they enable high-speed data transmission with low latency. For medical devices, they provide precise signal processing and reliable performance. In industrial control systems, these boards can withstand harsh environmental conditions while ensuring stable system operation.

Advantages:

- High assembly density, compact size, and lightweight design

- Enhanced reliability due to reduced interconnections between components (including devices)

- Increased routing layers providing greater design flexibility

- Capability to form impedance-controlled circuits and high-speed transmission circuits

- Configurable shielding layers (both electrical and magnetic) and metal-core heat dissipation layers for multifunctional needs

- Simplified installation with high operational reliability

Disadvantages:

- Higher manufacturing costs and longer production cycles

- Requirement for advanced reliability testing methods

- Being a product of electronics evolving toward high-speed, multi-functionality, large-capacity, and miniaturization

Multilayer PCB board or Multilayer circuit board plays an important role in the solution for the complex circuit requirements, as it improves the product performance and reliability. Contact FX PCB today to get a quote for your Multilayer PCBs.