Description

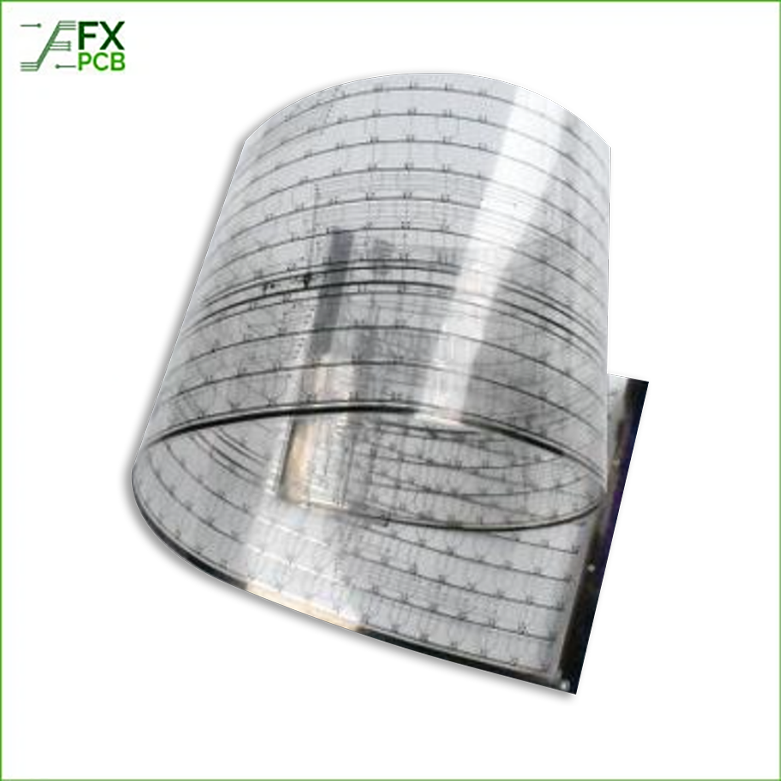

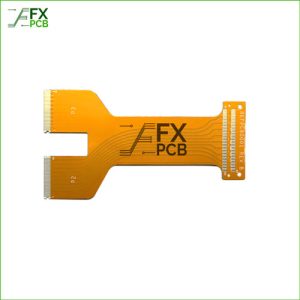

PET Flex PCBs: The Secret Weapon for Bendable Electronics

Let’s be honest – when your latest wearable design needs to survive being twisted, folded, and worn daily, standard rigid PCBs just won’t cut it. That’s where PET flex circuits come in, and they’re quickly becoming the MVP for designers who need reliable flexibility without the premium price tag of polyimide alternatives.

Why PET Flex is Stealing the Spotlight

We’ve been working with flex circuits for years, and here’s what we’ve learned about PET that makes it special:

- It bends like a gymnast (but won’t snap like a stale cracker)

- Costs about 30-40% less than polyimide options

- Handles sweat and moisture better than your phone’s “waterproof” case

- Weighs next to nothing – perfect when every gram counts

Real-World Wins We’ve Seen:

Remember that fitness tracker that kept failing during sweat tests? PET flex solved it. The disposable medical sensor that needed to be ultra-thin? PET made it work. These boards aren’t just theoretical – they’re proven in:

- Fitness tech that survives CrossFit workouts

- Medical patches that monitor patients for days

- Automotive sensors that handle engine vibrations

- Smart clothing that actually survives the washing machine

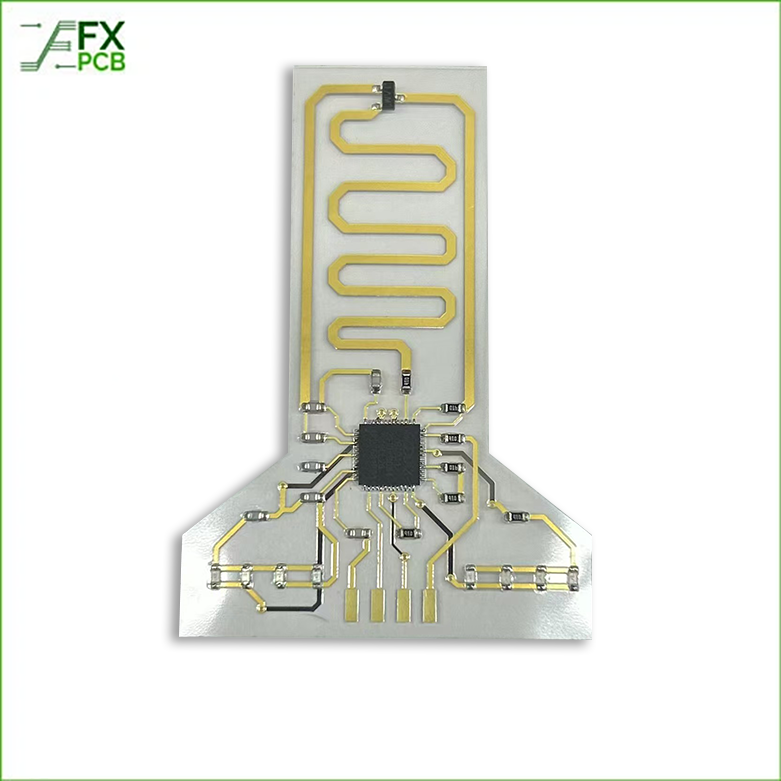

The Nerd Stuff (For the Engineers Reading This)

| Spec | PET Flex | Polyimide |

| Bend Cycles | 10,000+ | 50,000+ |

| Max Temp | 160°C | 250°C+ |

| Cost | $$ | $$$$ |

| Best When | You need affordable flexibility | You need NASA-level performance |

Pro Tip: If your design doesn’t involve jet engines or space travel, PET will probably do the job just fine while keeping your CFO happy.

Need Help Deciding?

We get it – choosing materials can be overwhelming. That’s why we offer:

- Free design reviews (we’ll tell you if PET will work)

- Samples to test (because seeing is believing)

- No minimum order quantities (start small if you want)

PET flex PCBs give you 90% of the performance at 60% of the cost of premium options. For most consumer and medical applications, that’s the smartest choice you can make.

Want to see real samples? Hit reply and FX PCB team will send you some to play with – no sales pitch, just good materials for your next breakthrough.