Description

Prototype PCB Assembly – Understanding Introduction

Prototype PCB assembly refers to the process of assembling and testing printed circuit boards (PCBs) before larger-scale production. PCB assembly is a critical part of any electronic product development process. Since every electronic device has different requirements and specifications, therefore prototype PCB assembly becomes an essential step for designing a complex electronic product from scratch. In this article, we will discuss prototype PCB assembly in detail, starting from the basic introduction to the step-by-step process involved in assembling a PCB.

What is a Printed Circuit Board?

A printed circuit board, commonly known as PCB, is a board used to hold and connect electronic components. PCBs can be used in a wide range of electronic devices, from simple equipment like an alarm clock to complex systems like a computer. PCBs provide numerous advantages over traditional wirings, such as simplified production, lower total cost, standardized design, and better quality.

PCBs are created by drilling holes into pads and mounting electronic components onto them. The components are then soldered onto the pads using a combination of heat, flux, and a soldering iron. Once the components are attached, the board is tested and validated to ensure proper operation.

Why is Prototype PCB Assembly Important?

Prototype PCB assembly is essential because it enables designers to test their designs before they go into mass production. This helps identify any errors or issues that may arise in the design, thus reducing the time and cost of the overall process. Without prototype PCB assembly, design errors could go unnoticed, leading to significant financial losses in later phases or even consumer harm.

Moreover, a prototype PCB assembly allows you to verify your design’s functionality before investing significant time and resources in the production process. This validation can help improve the performance and reliability of the end product, ultimately enhancing customer satisfaction.

Process of Prototype PCB Assembly

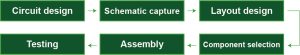

Prototype PCB assembly is an intricate process that involves multiple steps, including circuit design, schematic capture, layout design, component selection, assembly, and testing. The following is an overview of the prototype PCB assembly process:

Circuit Design

The circuit design forms the basis of any PCB assembly process. It involves creating a schematic diagram that shows how the various components in the electronic device are connected. Experienced designers like electric engineers or freelance electrical engineers use computer-aided design (CAD) software to create a schematic diagram that accurately reflects the requirements of the electronic device.

Schematic Capture

After creating the circuit design, the next step is to capture the schematic electronically in a CAD program. This includes entering the component values and symbols, which will later be used to generate a netlist. The netlist is simply a list of connections between various components in the schematic diagram. The CAD program then generates a layout design of the PCB.

Layout Design

The layout design translates the schematic diagram into a physical PCB layout. The layout design involves placing the electrical components on the PCB, routing the traces between these components, and defining power and ground planes. The goal of the layout design is to ensure proper signal integrity and reduce electromagnetic interference (EMI).

Component Selection

Component selection is an essential part of any prototype PCB assembly process. It involves selecting the right components such as resistors, capacitors, and integrated circuits that meet the requirements of the electronic device. A component selection must consider various factors such as the physical size of the component, electrical properties, and environmental factors like temperature, humidity, and vibration.

Assembly

Assembly is the process of mounting the selected components onto the printed circuit board. This involves placing the components onto the board, applying a solder paste, and then heating the board in an oven to melt the solder and attach the components. Once assembled, the board is inspected to ensure that all the components are securely attached and that there are no missing or damaged components.

Testing

After assembly, the board is tested to ensure that it functions as expected. Testing can range from simple continuity checks to sophisticated in-circuit testing using automated test equipment. This testing helps to identify potential electrical faults or flaws in the PCB, which can then be rectified.

Conclusion

Prototype PCB assembly is a crucial step in any electronic product development process. This process helps identify errors or issues with the design that may go unnoticed in later stages of production. A successful prototype PCB assembly reflects high-quality workmanship, ingenuity, and technical expertise.

It is vital to partner with an experienced and specialized PCB assembly company that has the necessary skills and expertise to handle your project’s complexities. While price is always a consideration, quality should not be neglected, as it can be costly in the long run. By paying attention to the PCB assembly process’s details, you can increase your success rate and build products that deliver highly profitable results in the mark

Whatever your production is – experimental, small-scale or mass, no matter how non-standard or large-scale your tasks are, we are ready to take on their solution. We are distinguished by deep industry expertise, as well as a colossal experience in implementing integrated innovative solutions and digital technologies for printed circuit board assembly in China in 2023.

IMPLEMENTATION OF THE CONCEPT PROVIDES

![]()

Manageability and control

based on intelligent automation

![]()

Production traceability

and digital passport of the product

![]()

Single information circuit

ERP/MES, equipment, personnel

![]()

Quality control

and minimization of the human factor

![]()

Reduction of production risks

and optimization of losses and downtime

![]()

Competitive cost

manufactured products

IMPLEMENTATION RESULT

The concept of PCB assembly production developed by the FXPCB team makes it possible to produce equipment that meets the most modern requirements for quality and manufacturability with high production efficiency. To make the construction of digital assembly and assembly production possible, we offer our customers a full range of solutions and services to ensure the achievement of planned goals.