Description

Different types of IMS PCB?

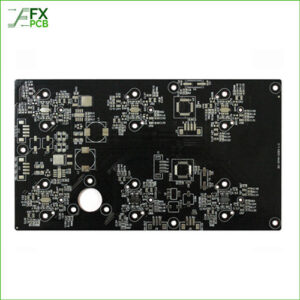

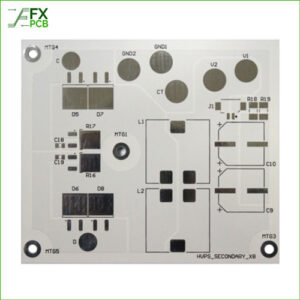

IMS (Insulated Metal Substrate) PCB which use metal as substrate material, usually we use Alu or Copper substrate. Below are FX PCB’s capabilities for IMS PCB

- Single-sided printed circuit boards

- Double-sided printed circuit boards

- Multilayer printed circuit boards

What are the applications of the IMS PCB board?

- Automotive electronics

- Consumer electronics

- Telecommunications

- Industrial instruments and control devices

- Medical electronics

- Energy systems

- Security systems

- Lighting systems

- Audio/video systems

Why do we need IMS PCBs?

IMS PCBs are used in a variety of electronic devices, from cell phones and computers to medical devices and industrial equipment. They are ideal for applications that require the most reliable electrical performance, such as:

- Higher frequency

- High speed

- High-power designs

IMS PCBs offer a number of advantages over traditional PCBs, including improved signal integrity, improved thermal management, and higher reliability.

IMS PCB VS FR4 printed circuit board

FR-4 is a type of glass fiber-reinforced epoxy laminate used for printed circuit boards (PCBs). FR-4 has high temperature and chemical resistance, making it suitable for high-strength applications.

It is also a cost-effective option for applications that require higher levels of electrical performance than standard FR-4. In contrast, FR-4 PCBs are much cheaper and easier to manufacture than PCBs made from other materials such as polyimide or Rogers.

They also provide better performance in high-frequency applications, although not as good as PCBs made from other materials. FR-4 PCBs also have higher dielectric strength than other PCBs, making them more suitable for applications that require high voltage.

9 Advantages of IMS

Higher density

IMS PCBs can provide higher electrical and thermal density than traditional FR-4 boards.

Less weight

IMS-printed circuit boards are significantly lighter than FR-4 counterparts due to the use of thinner dielectric layers.

Reduced complexity

IMS PCBs reduce design complexity by replacing multiple layers of traditional PCBs with a single layer.

Better performance

IMS PCBs provide better signal integrity and lower noise than traditional FR-4 PCBs, resulting in higher overall performance.

Greater reliability

IMS-printed circuit boards are more resistant to thermal and mechanical stress, which ensures greater reliability.

Improved thermal management

IMS PCBs can improve heat dissipation ability, reducing the risk of thermal damage to components.

Improved signal integrity

IMS PCBs provide improved signal integrity due to lower dielectric constant, resulting in less signal distortion.

Saving money

IMS-printed circuit boards reduce component costs through higher electrical and thermal density.

Greater design flexibility

IMS PCBs can be designed using a variety of materials and configurations, providing greater design flexibility.

Efficient heat dissipation

One of the main ones is the use of boards with a heat-conducting base. For effective heat dissipation, the board substrate must have low thermal resistance. It is defined as R = d / (σ · S), where σ is the specific thermal conductivity of the material, d is its thickness (length of the heat-conducting section), S is the cross-sectional area of the heat-conducting section.

Metals and substrates based on ceramic materials have the highest thermal conductivity. However, the latter, due to well-known reasons (cost, mechanical strength, impossibility of obtaining large boards, complexity of processing, etc.), are used only for special tasks.

Therefore, over the years, the use of printed circuit boards with a metal base has been expanding all over the world. Such boards are already widely used in LED devices, various current converters, electric drives, power supplies, welding equipment, etc.

How to choose an IMS PCB manufacturer?

- Look for experience: select an IMS printed circuit board manufacturer with a long and successful history in the industry. A reliable PCB manufacturer should have many years of experience in the industry and be up to date with the latest technologies and trends.

- Check out their quality guarantee: Quality assurance is the number one priority when it comes to IMS PCBs. You want to make sure that the manufacturer you choose has a proven track record of producing high-quality products.

- Consider their service offerings: Make sure the manufacturer you choose offers a wide range of services, such as design, manufacturing, assembly, and testing. This will ensure that you can get the most out of your PCB.

- Ask about their delivery times: Delivery times are important when it comes to IMS printed circuit board manufacturers. Make sure the manufacturer you choose can meet your deadlines and deliver the product on time.

- Think about their prices: Price is always a factor when choosing a PCB manufacturer. Make sure the manufacturer you choose offers competitive prices and can provide you with the best value for money.

Summary

IMS PCB Manufacturer is popular because it offers some advantages. IMS PCBs are more thermally efficient than regular FR-4 PCBs because they use a metal core that can dissipate heat more efficiently. This makes them ideal for applications where heat management is critical.

Additionally, IMS PCBs are more resistant to vibration and shock, making them ideal for applications where these elements are important. Finally, IMS PCBs are generally lighter and thinner than conventional FR-4 PCBs, making them well-suited for applications where size and weight are an issue.