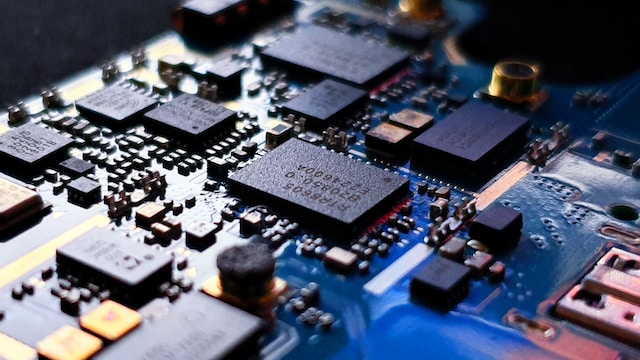

Imagine opening up your smartphone, computer, or any electronic device, and you’re likely to find a tiny, intricate marvel called a circuit board. These circuit boards are essential components that enable the functionality of our everyday gadgets. While most circuit boards come in various colors, the blue circuit board stands out with its striking appearance and unique features. In this article, we will delve into the world of blue circuit boards, exploring their purpose, advantages, manufacturing process, applications, and future prospects.

The modern-day electronics world depends heavily on the Printed Circuit Boards (PCBs) as its backbone. A PCB is a medium to transfer the current through its copper pathway and it dissipates the heat to keep the tiny yet highlycomplex electronic equipment on it in perfect condition.

If you are to get the best PCBA and PCB for your digital devices, you have to know this PCB assembly process thoroughly. FX PCB with its years of experience understands this need and thus, we present you the detailed guideline.

FX PCB dont follow the standerd manufacturing process is no exception to it. Our process includes solder pasting on the PCB base, placing the electronic components in the right place, soldering them with the PCB, checking the accuracy, final inspection, and delivery to customers.

Before we dive into the world of blue circuit boards, let’s first understand what circuit boards are and how they work. In simple terms, a circuit board, also known as a printed circuit board (PCB), is a flat board made of non-conductive material like fiberglass or composite epoxy. On this board, various electronic components, such as resistors, capacitors, and integrated circuits, are mounted and interconnected using conductive pathways or “traces.”

The history of circuit boards dates back to the early 20th century, and they have come a long way since then. From bulky, hand-wired circuits to compact PCBs, the evolution has been remarkable. This section will explore the technological advancements that paved the way for the development of blue circuit boards, which have become an integral part of modern electronic devices.

Blue circuit boards offer several advantages beyond their aesthetic appeal. In this section, we will explore the benefits of using blue solder masks in PCBs, including improved aesthetics and visibility. Additionally, we will delve into how blue circuit boards find applications in various industrial sectors, making them an ideal choice for specific use cases.

The manufacturing process of blue circuit boards is a sophisticated and precise procedure that involves several steps to create these intricate electronic components. Blue circuit boards are known for their eye-catching appearance and are widely used in various electronic devices, from smartphones to aerospace applications. Let’s take a closer look at the step-by-step process of manufacturing blue circuit boards:

The first step in the circuit board manufacturing process is the design of the PCB. Engineers and designers use computer-aided design (CAD) software to create the layout of the circuit board. This process involves determining the placement of components, the routing of traces, and the overall size and shape of the board. During the design phase, specific attention is paid to the placement of the blue solder mask, which will give the circuit board its distinctive appearance.

Once the design is complete, the next step is to select the materials that will be used to create the blue circuit board. The base material is typically a fiberglass-reinforced epoxy known as FR-4, which provides the necessary structural support for the board. The blue solder mask, which is responsible for the circuit board’s color, is made from a specialized epoxy-based ink that contains pigments to achieve the desired shade of blue.

The fabrication process starts with the preparation of a copper-clad laminate sheet, which is essentially a thin layer of copper bonded to the FR-4 substrate. The design information is then transferred to the laminate through a process called photolithography. This involves using a photosensitive layer (photoresist) that is exposed to ultraviolet light through a mask containing the circuit pattern. The unexposed resist is then removed, leaving behind the copper traces required for the circuit.

After the photolithography process, the exposed copper traces are subjected to an etching process. An etchant, usually an acidic solution, is used to dissolve the unwanted copper, leaving only the desired circuit traces. The blue solder mask is applied to the board, covering the copper traces while leaving openings for component placement.

The blue solder mask is applied to the board using a screen printing process. A screen with openings corresponding to the areas where the solder mask is required is placed over the PCB, and the blue ink is applied through the screen onto the board. The blue solder mask provides several benefits, including protection from environmental factors, improved insulation, and easier identification of components during board assembly and repairs.

Once the blue solder mask is applied, the next step is to place the electronic components on the board. Surface-mount components (SMDs) and through-hole components are soldered onto the PCB according to the design specifications. The blue solder mask assists in guiding technicians during this assembly process by providing clear visual indicators for component placement.

After component placement, the board goes through a soldering process to secure the components in place. There are various soldering methods, including wave soldering and reflow soldering, depending on the type of components used. The blue solder mask plays a crucial role in protecting the areas where soldering is not required and preventing solder bridges between closely spaced traces.

Before the blue circuit boards are deemed ready for use, they undergo rigorous quality control and testing. Automated optical inspection (AOI) machines and functional testing equipment are used to check for any manufacturing defects or faulty connections. Any issues detected during testing are rectified before the boards are approved for shipment.

After passing quality control checks, the blue circuit boards are finalized, and any necessary finishing touches are made. This may include applying a protective coating to safeguard the board from moisture and other environmental factors. Finally, the blue circuit boards are carefully packaged and prepared for distribution to electronics manufacturers and other customers

Blue circuit boards find applications in a wide range of electronic devices. From smartphones to automobiles, they play a crucial role in modern technology. In this section, we will explore the diverse applications of blue circuit boards, showcasing how they contribute to the functionality and reliability of various consumer and industrial products.

Green has been the traditional color choice for circuit boards, but blue has gained popularity in recent years. In this section, we will compare blue circuit boards with other color options, such as red and green, analyzing the pros and cons of each choice. This will help readers understand the distinct advantages that blue circuit boards bring to the table.

When designing a blue circuit board, several critical factors must be considered to ensure optimal performance and reliability. This section will delve into the design considerations specific to blue PCBs, guiding designers on how to make the most of the blue solder mask to achieve functional and visually appealing results.

As with any electronic component, issues may arise with blue circuit boards. This section will cover common problems faced by blue PCBs, offering troubleshooting tips and maintenance advice. While some issues can be resolved independently, we will emphasize the importance of seeking professional assistance for more complex problems.

Technology is constantly evolving, and blue circuit boards are no exception. In this section, we will explore the latest advancements in materials, manufacturing techniques, and designs for blue circuit boards. Additionally, we will speculate on future trends and their potential impact on the electronics industry.

With the increasing concern for the environment, the electronic waste generated by discarded devices is a significant issue. This section will focus on the environmental impact of blue circuit boards and discuss recycling and waste management strategies. We will also explore sustainable practices in PCB production, aiming to minimize the ecological footprint of electronic devices.

As with any technology, myths and misconceptions surround blue circuit boards. This section will debunk common myths, separating fact from fiction. By clarifying misconceptions, readers will gain a better understanding of the truth behind blue PCBs.

The Future of Blue Circuit Boards

In this section, we will look into the future of blue circuit boards. Based on current developments and trends, we will make predictions about the potential growth and expansion of blue PCBs. From innovative applications to their integration in the Internet of Things (IoT), the future of blue circuit boards is full of possibilities.

Blue circuit boards have evolved from simple electronic components to sophisticated technologies that power our modern world. The blue solder mask not only enhances their appearance but also provides functional benefits, making them a preferred choice in various industries. As technology continues to advance, blue circuit boards are set to play an even more significant role in shaping the future of electronics.

Blue circuit boards typically don’t cost more than their counterparts in other colors. The difference in price, if any, is usually negligible.

Yes, blue circuit boards are suitable for high-temperature environments, as long as the materials used can withstand the temperature requirements.

Yes, blue circuit boards are compatible with lead-free soldering processes, which are more environmentally friendly.

No, the color of the circuit board, including blue, does not affect the performance of electronic devices. The functionality relies on the design and quality of components.

Yes, blue circuit boards, like other PCBAs, can be recycled through appropriate electronic waste recycling facilities to minimize their environmental impact

I am Peter Gong. I have been working in PCB and PCBA industry for 15+ years now. I have been a part of the PCB revolution with my dedication to circuit board technologies and creative ideas. I write in FX PCB to impart my knowledge on PCB and PCBA for all circuit board lovers, manufacturers, and users.

WhatsApp us