Electronic device design initiates with a choice that rarely makes headlines but quietly defines its future. Before any chip is placed or any software is written, engineers must decide how the device will physically carry its intelligence. This decision concerns the types of Printed Circuit boards used in PCBA: Rigid, Flexible, or Rigid-Flex.

Next, you will learn about these three distinct PCB types, not as mere components but as strategic design tools that shape how modern technology lives, moves, and endures.

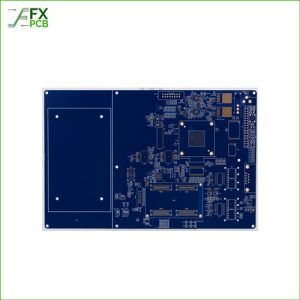

The Rigid PCB: The Engineer’s First Blueprint

The rigid PCB is the silent standard as it is also considered the steel beam of the electronic world, unmoving, unbending, unwavering.

- Material Truth: Made from solid substrates like FR4 fiberglass, these boards are as stiff as the device needs them to be. They provide uncompromising stability for components, just like a city with concrete roads, traffic signals, and permanent buildings. That’s what a rigid PCB is for: your device’s internal logic.

- When Stillness is Strength: From microwaves to motherboards, rigid PCBs are used where movement is neither needed nor welcome. Their architecture invites mass production. Their reliability reduces failure. Their simplicity shortens timelines. For products that live in one place, rigid is the blueprint of choice.

But here’s what people rarely say: rigid PCBs have a psychological impact. They dictate the device’s form. They don’t follow your design. They lead it. Want curves? Want folding screens? Want embedded intelligence in a wearable ring? Rigid boards will be your first limit.

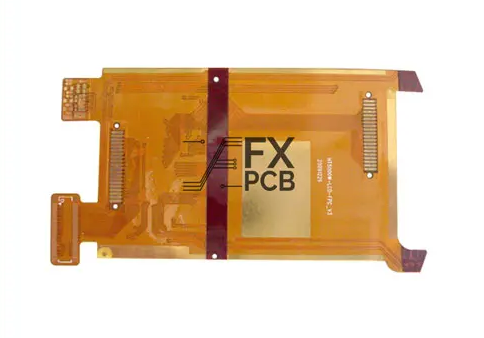

The Flex PCB: Blueprint of Motion

If rigid PCBs are buildings, flexible PCBs are origami. They bend, twist, and coil into the tightest of enclosures. But this isn’t about flexibility for the sake of novelty; this is the following function in its purest sense.

- The Language of Movement: Built on thin, elastic materials like polyimide, flex PCBs aren’t simply “foldable.” They’re transformational. They allow circuits to exist not just inside straight boxes, but in cylindrical probes, curved implants, or rollable displays.

- Where They Live: They are in cochlear implants. In fitness bands. In drones. In instruments that must fit in crevices smaller than a fingernail. Flex PCBs answer questions that rigid boards can’t: What if the board must move with the product? What if the circuit needs to vanish into space?

- Designing the Invisible: Here’s the paradox. Flex PCBs seem simple. But they demand a new way of thinking. Engineers must design not just in width and height, but in dynamic shape. Every bend radius matters. Every twist must be tested.

Flex isn’t just a format. It’s a philosophy. One where electronics no longer need to dominate space, they disappear into it.

The Rigid-Flex PCB: The Circuit that Breathes

The name may sound like a compromise. It’s not. A Rigid-Flex PCB is a singular innovation. It is a system that doesn’t just live in both worlds, but thrives in them simultaneously.

- An Integrated Intelligence: A Rigid-Flex PCB is built by fusing layers of rigid boards with flexible circuits. Think of a robotic spine where the vertebrae are rigid, but the ligaments between them are elastic. That’s the essence of this architecture.

- Why It Exists: Sometimes, a product must be both compact and rugged, mobile and high-performance. Medical imaging systems, Advanced cameras, Military drones, and all high-end consumer electronics that fold, flip, or transform, Rigid-Flex PCBs make this possible, connecting modules across hinges and folding seamlessly without cables or connectors.

- Silent Superiority: Here’s what rarely gets said: Rigid-Flex isn’t just a functional improvement. It’s a system design revolution. It removes the weakest links of connectors and cables. It reduces points of failure. It simplifies assembly. And yet, it asks more from the design phase: precise alignment, material balance, thermal consideration.

To choose Rigid-Flex is to accept complexity early, so the product can behave simply later.

PCBA: Where Choices Become Reality

Design ends on a screen, while PCBA begins on a factory floor. The Printed Circuit Board Assembly (PCBA) process is where theory becomes performance. Here, each component is mounted, soldered, and tested not just for function but for life in the real world.

- Rigid PCBs: Assembly is straightforward. Pick-and-place machines operate with mechanical confidence. Soldering is predictable. Defects are rare. Production is swift.

- Flex PCBs: Assembly demands care. Excess heat can deform the substrate, and mechanical stress can break traces. Fixtures must adapt, and processes must evolve.

- Rigid-Flex PCBs: Assembly is both art and engineering. Each fold is calculated, and each material layer reacts differently to reflow. The reward? A board that behaves like a single entity, even across multiple behaviors.

The difference between these board types doesn’t end with their form. It flows into the very act of building, of testing, of scaling.

Choosing the Right PCB: A Design Ritual

This choice must be made before a product moves, glows, or is prototyped.

Rigid is for structure. Flex is for freedom. Rigid-Flex is for ambition.

Ask yourself:

- Will this product move, twist, or fold?

- Will weight and space shape the user experience?

- Will reliability matter more than price?

- Will design need to transform, not just perform?

A PCB is not just a technical platform; it’s the first expression of your product’s personality.

In Conclusion

In a world where devices are getting thinner, smarter, and more adaptive, your PCB must evolve too. Rigid boards will always have a place. Flex boards will always open new doors. But Rigid-Flex, this is where the frontier lies. This is where devices become wearables, where screens wrap around wrists, and where circuitry becomes part of design, not hidden beneath it.

At FX PCB Co., we don’t just manufacture boards. We partner in the early decisions that shape your product’s story. You might be creating an industrial control unit, a wearable sensor, or the next breakthrough medical device. We offer expertise in Rigid, Flex, and Rigid-Flex PCB design and assembly, ensuring your circuits don’t just work, they belong.

Let’s design what hasn’t been designed yet. Contact FX PCB today. Your product’s future is waiting to be built, one layer at a time.

Also Read: