Description

What are single-sided printed circuit boards?

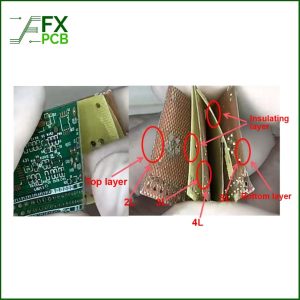

Single-sided printed circuit boards is also called single-layer PCBs, are the simplest and most basic circuit boards. The copper foil layer is only on one side, and the other side is normally covered by a solder mask or left as base material. Components and traces are mostly located on the copper foil side, while holes are used to connect component leads or Pins through the board to establish the electrical connections.

Production Process:

- Cut Lamination: Cut the base material to the required size per the MI(Manufacturing instruction)

- Drilling: Drill the tooling holes and vias on the substrate

- Outer Layer Imaging: Transfer the circuit pattern onto the substrate using photosensitive coating.

- Etching: Remove the unprotected copper foil through etching to form the circuit traces

- Inspection: Check the quality of the etched circuit board

- Solder mask: Apply a solder mask layer to prevent solder from flowing to unintended areas during soldering

- Silkcreen: Print the marking on the PCB, such as part number, component designations, date and etc

- CNC: using punching or routing to make the final product outline

- Surface treatment: OSP, HAL Leadfree, HASL, ENIG

- Test: using a flying probe test or test fixture to do the electrical test to ensure there is no open or short circuit.

- Packaging & Shipping: Pack the final product and ship it to the customer

Different kinds of materials for the single-sided Printed Circuit boards.

94HB and 94V0 are paper-based CCL (copper clad laminate), but 94HB is the lowest-grade board without flame-retardant properties, and it can’t be used for the power supply board. While 94V0 is a flame-retardant with higher safety standards.

22F is a single-sided semi-glass fiber board, normally processed with punching.

Cem-1 is a paper base with epoxy resin, laminated with double-sided glass fiber cloth, then hot-pressed with copper foil. Its mechanical strength, moisture resistance, flatness, heat resistance, and electrical performance are better than the paper-based CCL (94HB and 94V0). This makes Cem-1 is more suitable for high-requirement PCBs, for example, TV tuners and power switches, and it is also widely used in TVs, recorders, radios, and other electronic devices.

Cem-3 is manufactured by impregnation a glass mat with epoxy resin, then laminating it with double-sided glass fiber cloth and copper foil under heat and pressure. Compared to Fr4, Cem-3 replaces most of the woven glass fiber with glass mat, significantly enhancing its mechanical flexibility.CEM-3 exhibits slightly inferior thickness control and dimensional precision compared to FR-4, and PCBs made with CEM-3 are more prone to warping after soldering processes.

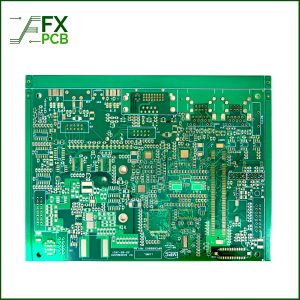

FR4 as the representative of glass fiber epoxy resin, plays an important role in the electronics industry due to its excellent flame retardancy, high strength, heat resistance, and dielectric properties. It is the most popular material used for single sided printed circuit board.

The Delivery time of a Single-sided Printed circuit board

As the single layer PCB is normally very easy, and the mass production can be finished in 1-2 weeks. The sample will be delivered in 3-5days, but you can always choose to expedited the delivery time to 24 hours with additional cost.

The Application

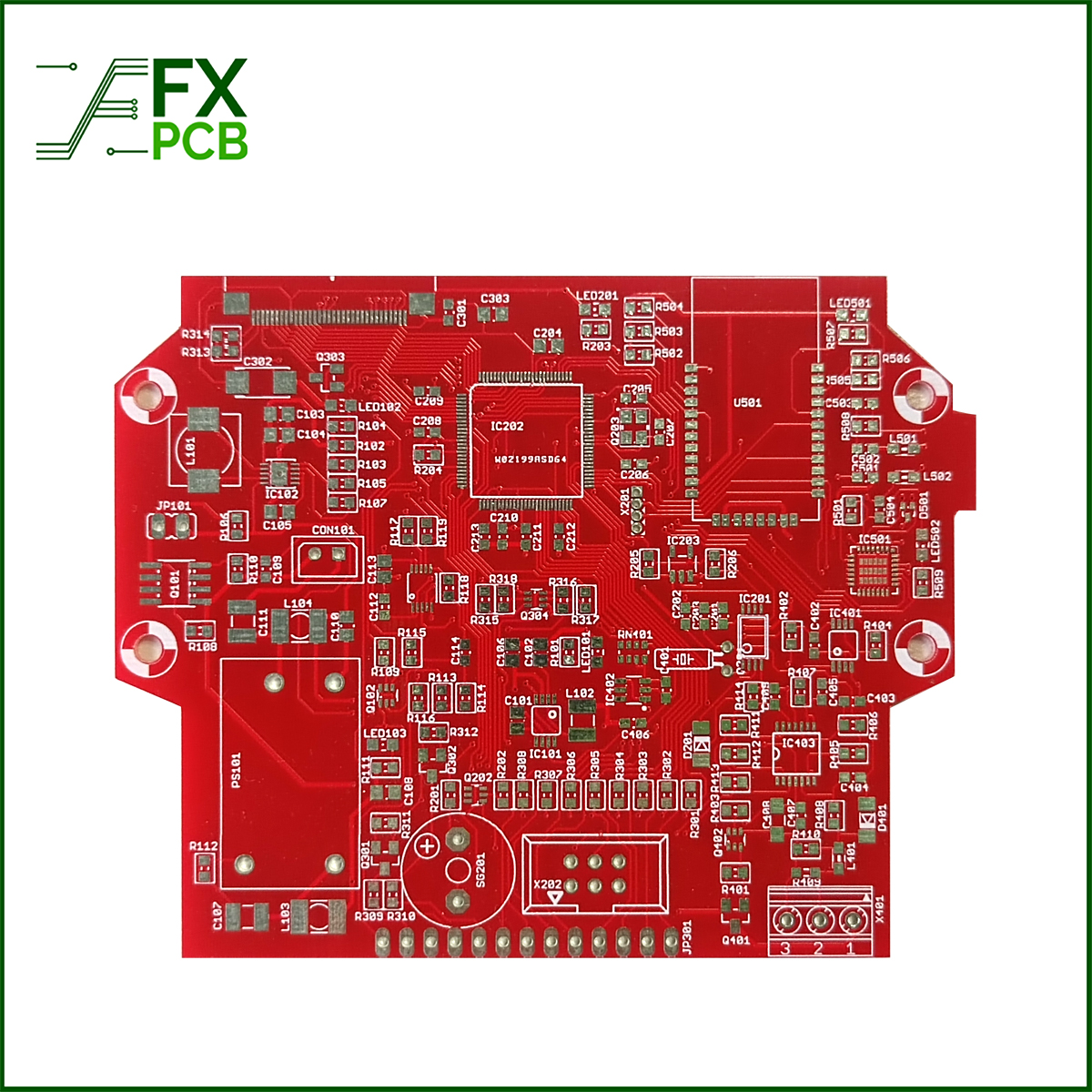

The low cost and easy to produce makes the single-sided printed circuit board are widely used in various electronic equipment, such as LED, power supply , electronic toys and etc.

FX PCB is an ISO9001 certificated PCB Supplier, and we can send the best price and quality for your single-sided printed circuit board. Contact us today to get a quote