As you design your electronics today, your choice of PCB lays the foundation for tomorrow’s success. Whether you lean toward a simple single‑layer board or a more complex multi‑layer design, that decision matters. Many Pcb Board Suppliers offer both options, but which one fits your needs?

This blog guides you through the benefits and trade‑offs. We keep it clear and direct. By the end, you will understand when to choose single‑layer or multi‑layer PCBs. Let’s dive in.

Single‑Layer vs Multi‑Layer PCBs – Which One Should You Choose?

What Is a Single‑Layer PCB?

A single‑layer PCB has one copper layer. It’s simple. It has one side for traces. You place components on the other side. It is cheap, easy to make, and suits basic circuits. For low cost and fast prototypes, single‑layer is ideal.

Advantages of single‑layer:

- Low cost.

- Quick to manufacture.

- Easy to test and repair.

Limitations:

- Limited routing space.

- Not good for complex circuits.

- Harder to reduce size.

What Is a Multi‑Layer PCB?

A multi‑layer PCB stacks several copper layers. You separate them with insulation. You connect layers with vias. That gives more routing. You can fit complex circuits, shrink the board and improve signal integrity.

Advantages of multi‑layer:

- High routing density.

- Smaller size.

- Better electrical performance.

- Useful for high‑speed designs.

Limitations:

- Higher cost.

- Longer manufacturing time.

- Harder to repair.

Key Comparison

| Feature | Single‑Layer PCB | Multi‑Layer PCB |

| Cost | Lower | Higher |

| Manufacturing time | Shorter | Longer |

| Routing capability | Basic | Complex |

| Size efficiency | Larger footprint | Compact design |

| Signal performance | Basic | High performance |

| Repairability | Easy | Challenging |

Factors to Consider When Choosing

1. Circuit Complexity

Ask how many traces and components you need. If your design is simple, a single‑layer board works. If it is complex, multi‑layer is better.

2. Cost and Budget

Single‑layer costs less. It is reliable and fast. Multi‑layer costs more. If you need more performance and compact size, choose multi‑layer.

3. Lead Time

You need boards fast? Single‑layer is quicker. But a top Pcb Manufacture can also deliver multi‑layer in a short time, depending on capacity.

4. Signal Integrity and Speed

High‑speed signals need controlled impedance. You need internal ground and power planes. That is easier with multi‑layer.

5. Size Constraints

If space is tight, multi‑layer helps reduce footprint. This is useful for compact consumer electronics, medical devices, or wearables.

Role of Pcb Board Suppliers and Pcb Manufacture in Your Choice

When you work with Pcb Board Suppliers, ask clear questions. Ask about their experience with single‑layer and multi‑layer PCBs. Good suppliers explain the trade‑offs. They guide you to the right choice.

For Pcb Manufacture, look at their facility and processes. Do they support multi‑layer with internal layer alignment, offer fast turn or prototype services and test each layer? These matter.

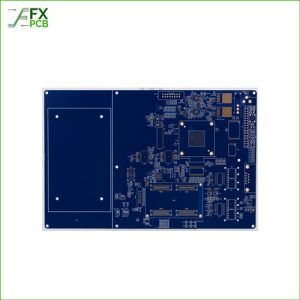

FX PCB is a trusted Pcb Board Supplier and Pcb Manufacture. We handle both types with equal care. We help you pick the most cost‑effective and reliable option.

Use Cases for Each Type

Ideal for Single‑Layer PCBs:

- Basic circuits or simple control boards.

- Low‑volume prototypes.

- Educational kits and hobby projects.

- Cost‑sensitive, quick turn products.

Ideal for Multi‑Layer PCBs:

- High‑density boards like motherboards or graphics cards.

- RF, high‑speed digital, or multi‑power designs.

- Compact devices (e.g. handheld, medical, wearables).

- Products that need EMI control or reliable power distribution.

Why Choosing the Right PCB Type Impacts Your Final Product

The type of PCB you choose doesn’t just affect cost. It influences product performance, size, and reliability. Many companies overlook this during the early design phase. But the truth is, selecting the wrong type can lead to signal issues, delays, or even redesigns. That’s why experienced Pcb Board Suppliers and manufacturers recommend thinking ahead. Your end-use application, component density, and speed requirements all affect the ideal board choice. A bit of foresight saves a lot of money and time later.

Key reasons why your PCB choice matters:

- It affects final product size and layout.

- It influences signal integrity and power stability.

- It impacts long-term durability and serviceability.

- It plays a role in production time and scalability.

- It determines total production and assembly cost.

Working with a trusted Pcb Manufacture ensures these factors are properly considered from day one.

When to Choose What: A Quick Guide

- Simple design, tight budget, fast turn? → Choose single‑layer.

- Complex design, faster signals, small size? → Choose multi‑layer.

- Unsure? → Contact your Pcb Board Suppliers or Pcb Manufacture. Ask for advice.

How FX PCB Can Help You Decide

FX PCB has over a decade of experience in serving businesses worldwide. We are a top PCB manufacturer from China. Our team handles both single‑layer and multi‑layer boards. We deliver fast quotes. We offer prototypes and volume runs. Our ISO‑certified facilities follow strict standards. We help you choose what fits your project best. We support you at every step—from design questions to final delivery.

Wrapping Up

Both single‑layer and multi‑layer PCBs have their place. The right choice depends on cost, complexity, size, and performance needs. Always talk to reliable Pcb Board Suppliers and Pcb Manufacture. Ask for clear guidance. Choose what fits your project today—and tomorrow.

Ready to move forward? Contact FX PCB for expert assistance. Let’s build your future together.

FAQs

Q1: Is a multi-layer PCB always better than a single-layer?

Not always. Multi-layer PCBs offer more features but are costlier. If your design is simple, a single-layer board is more efficient.

Q2: Can single-layer boards handle modern electronics?

Yes, for basic devices like LED circuits, calculators, or simple controllers, single-layer is perfect.

Q3: Are multi-layer PCBs harder to repair?

Yes. They are more complex and layered internally, making manual repair more difficult compared to single-layer boards.

Q4: How do I choose the right Pcb Board Suppliers?

Look for experience, certifications, and customer service. A good supplier helps you decide what’s best for your project.

Q5: Can FX PCB handle both single and multi-layer projects?

Absolutely. FX PCB offers full support for both types, from design to delivery, with quick quotes and quality assurance.