PCB or printed circuit boards have brought a breakthrough revolution in the communications and electronics industry. These PCBs are available in a variety of shapes and sizes, and at times, you might require cutting them to fit your operational requirements.

So, did you even think about cutting a PCB?

I guess even if you have tried to cut these boards at home with a manual PCB cutter or a PCB cutter tool, you have found the entire process clunky.

So, for your convenience, today’s tutorial will discuss how to cut PCB at home or workspace with ease.

So, are you up for it?

The glass substrate has unique advantages in the flatness, transparent, deformation, heat resistance, tear-resistance, etc, the deformation rate is very low under the high temperature working for a long time, the glass PCB can 360-degree luminescence, 80 color rendering index can be 140lmw or more, it doesn’t need to add the heat sink, and there is no light attenuation.

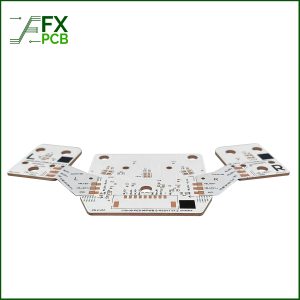

FX PCB developed its own technology on the glass PCB, which can greatly improve the copper thickness and adhesivity on the glass, please see FX PCB capability, and the advantage compared to other glass PCB technology. Order Now!

PCBs comprise of copper lines along with the glass-reinforced plastic. When you purchase a large piece of the printed circuit board, it allows you to cut it into smaller pieces and engage in works as you need.

The process has two steps:

The cutting process can be done using multiple PCB cutting tools. We will be discussing this equipment in the following sections. Now, let’s take a look at both steps with details.

Dremel is a famous American power tool manufacturer. They manufacturer some great power tools out of which their rotatory device is the most popular. Nonetheless, the Dremel rotatory come beneficial to cut PCBs with ease.

The process steps include:

If you don’t own a PCB cutting tool, there’s also an alternative to cut the board with a homemade PCB cutting machine.

For this, you will need to collect a 12V DC motor drill. Then you will have to prepare the sliding mechanism for the cutting machine. Use a motor bracket and adaptor to help the sliding mechanism run on the table where you will cut the boards.

Lastly, you will require a circular saw blade to cut the printed circuit board.

Once you have collected the blade, then, find a wood piece to create the surface for the cutting machine. After that, saw away right on the wood surface to create depth so that the saw blade can move freely on it.

Now assemble all the parts, including the motor, adaptor, and motor bracket. Make sure all these are arranged in perpendicular sideways so you can perform the required 90-cuts on the printed circuit boards.

To install the sliding mechanism, use screws. It will hold the sliding mechanism tightly on the position enabling you to cut with the highest accuracy. Once the tool is ready, you can insert the circuit board in it and perform the required cut.

If you have an unused or extra circuit board, you can actually use it to make interesting jewelry, such as earrings. Yes, it’s possible if you are ready to unleash your creativity.

For this, get a damaged or old PCB at first. After that, outline the earring shape on it using a sharpie. Then use the Dremel rotatory tool and saw blade to cut away the outlined shape. Lastly, spray golden paint on it or silver and let the PCB board soak.

Also, make a hole in the middle to add strings to wear it in the ear. That’s it, and you now own an exotic electric circuit board made jewelry.

Whether you use the cut PCB for electronic devices or jewelry, you will require to sand it for the necessary polish-ness. For this, use a200 grits sandpaper. Keep sanding until the edges become smooth. Lastly, use a rag to wipe off the excess dust from the board’s surface.

PCBs have transformed the whole world with its brilliance and versatile usability. So, when you follow the aforementioned steps to thoroughly understand how to cut PCB in different shapes and sizes, you unleash a myriad of multitasking with the PCBs.

Hope, it comes handy for all electricians and mechanics who every day come across the printed circuit boards for one reason or another.

I am Peter Gong. I have been working in PCB and PCBA industry for 15+ years now. I have been a part of the PCB revolution with my dedication to circuit board technologies and creative ideas. I write in FX PCB to impart my knowledge on PCB and PCBA for all circuit board lovers, manufacturers, and users.

WhatsApp us