Description

What is PCBA ISO13485

PCBA ISO13485 requires the manufacturer to record all the manufacturing process data to ensure the production is controlled as standard, and it also requires risk management and process control in detail. PCBA ISO13485 certification also means the PCBA manufacturer understands and meets the requirements outlined in the certification, and it has the necessary systems and processes to ensure the orders are finished to a stable quality.

Why do we need to use ISO13485 PCBA?

As we know, medical devices play an important role in saving the patient’s life when they are in danger, and these medical devices must be produced to the standard. ISO 13485 is the international standard for medical device quality management systems , and it is essential for PCBA manufacturers serving this industry. The ISO13485 PCBA will be required for medical device approvals in many countries, as the risk management and traceability make the patient safer and the device more reliability.

The application of ISO13485 PCBA

- Medical Equipment Manufacturing: Complex devices such as X-ray machines, CT scanners, ultrasound equipment, and MRI systems all incorporate PCBAs.

- Portable Medical Devices: Devices like blood pressure monitors, glucose meters, and ECG machines require compact, low-power PCBAs.

- Health Monitoring & Telemedicine: PCBA manufacturing supports smart health monitoring devices that track vital signs and transmit data to healthcare professionals.

- Medical Robotics: Medical robots used in surgery, rehabilitation, and drug administration rely on high-precision PCBAs for accurate operation.

- Drug Delivery Systems: These systems depend on sophisticated electronic controls to ensure precise dosage and timing.

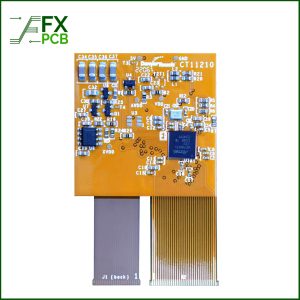

FX PCB – An ISO13485 PCBA supplier

1,Comprehensive Quality Management System

FX PCB has established a complete quality management system, and we adhere to the ISO 13485 PCBA standards at each processing stage from raw material procurement to finished PCBA. Through strict supplier qualification and incoming material inspection to ensure all components can meet the medical grade standards

2,Advanced production equipment and Technology

FX PCB has the advanced equipment, including high-precision SMT placement machines, AOI machines, X-ray equipment, etc. These machines can ensure superior precision and consistent product quality.

3,Professional Team

As an ISO13485 and ISO9001 company, we have an experienced team in medical-grade PCBA manufacturing processes. We provide the services from prototype to mass production. All of our team members will do regular training to ensure we master the latest industry standards and technologies

4,Strict Quality Control

The company implements the six-stage inspection process, which includes the SPI, 3D Automated Optical inspection, and X-ray inspection. These methods can find out the potential quality issues at early stages, ensuring all the PCBA will comply with ISO13485 standards.

No matter customer requires a quick turn PCBA prototype ISO13485, or mass production, FX PCB is always here to meet your standard. Send us your PCB Gerber file and Bom list to get a quote today.