Desoldering the connections from the circuit board are vital for replacing or salvaging electronic components when these are damaged. And when it comes to how to clean solder off a circuit board, you can opt for many methods.

You can use a soldering pump or braided equipment or even a compressed air device to solder off the circuit board. We will thus, discuss the essential tips to remove solder from pads. So, without much ado, let us start the tutorial.

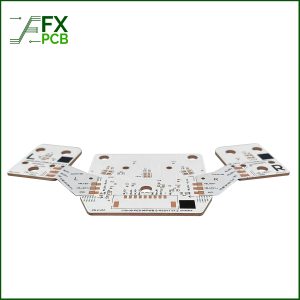

FX PCB can provide the ALN(Aluminum oxide) and AIO203(Aluminum Nitride) Ceramic PCB, we can make ENEPIG, ENIG, Immerison silver surface,you can check the material datesheet and our capability from the below tables.

Ceramic PCB is actually made of electronic ceramic materials and can be made into various shapes.

The ceramic circuit board has the following characteristics: high-temperature resistance, high electrical insulation, low dielectric constant, low dielectric loss, high thermal conductivity, good chemical stability, and the thermal expansion is almost can be coefficients of components.

You can use a soldering pump, iron or even an air compressor to remove solder from the circuit board. The good news is that none of these desoldering methods ischallenging.

When it comes to removing stubborn solder from the metal PCB or ceramic PCB, you can use a desoldering pump or iron for the process. The soldering pump is also known as a solder sucker or vacuum device.

It removes the melted solder from the circuit board components. The process includes the following steps:

The first step of using a soldering pump is to clean off the terminal from unnecessary debris and rust. Use isopropyl or rubbing alcohol on the circuit board terminals to wipe off the residue. You need to apply the isopropyl alcohol on the soldering side and not on the electric components.

After using rubbing alcohol, use a soft-bristled toothbrush to wipe off the debris from the solder parts gently.

It often happens that excessive heat of a soldering iron will damage the electric components on the other side of the circuit board. The damage may occur on the transistors, resistors or even in the integrated circuits (ICs).

So, you need to bring down the heat of the soldering pump or iron into a more manageable point. Thus, we recommend you use a metal alligator clip. The metal part of the pin will absorb heat and dissipate the heat.

You need to attach the clip in between the electric terminal and component of the circuit board to reduce the heat effect of the soldering iron or pump.

Often the tip f the soldering iron contains debris, especially soldering material. It hampers a neat and clean desoldering of the circuit board. So, the tip must be clean.

For it, turn on the soldering pump at first. After that, wait for three minutes to allow the tip heat up adequately. Then, push it on a clean sponge for cleaning. You should push the soldering iron from the tip to down for cleaning.

Also, use a wet sponge for better results.

Now push the soldering iron right on where you want to clean solder off from the circuit board. Keep pressing the solder iron tip until it connects with the soldered section of the circuit board. Once the tilt latches with the depressed point, heat the location with the iron.

Once you hold down the soldering iron properly on the location, the heat will start melting the solder from the board. Then apply the soldering pump and connect it on the melted portion of the solder pad to create the vacuum.

You will have to release the spring using a push button. Once removed the piston of the soldering pump will shoot back immediately. The created vacuum in the process will then pull up the melted solder part towards the pump.

Now remove the vacuumed solder into the trash and then carefully wipe off the recently wiped off circuit board pad. You will be amazed at your desoldering skills.

If you want to clean solder off a circuit board without using heat, using a compressed air machine is your best alternative. The compressed air inside the can will merely blast the solder away from the circuit board using its high pressure. The process is also ideal when it comes to how to remove solder without a pump.

Sometimes the speaker terminal of connections between two speakers or audio devices may get damaged. Then, you need to remove it for replacing. Also, if you want to fix the problems of the speaker terminal, you may need to replace several components from the circuit board.

You can use the soldering pump, iron or braided desoldering gear for the purpose. The processes have been described adequately on the tips mentioned above.

Sometimes you may need to remove solder from the copper PCB. We recommend you use a desoldering braid for the purpose.

The methods of how to clean solder off a circuit board can be tricky if you don’t know the processes elaborately. That’s why we have described each of the steps with proper explanation and care for your convenience. So, you shouldn’t face any problem with the cleaning solder off a circuit board anymore.

I am Peter Gong. I have been working in PCB and PCBA industry for 15+ years now. I have been a part of the PCB revolution with my dedication to circuit board technologies and creative ideas. I write in FX PCB to impart my knowledge on PCB and PCBA for all circuit board lovers, manufacturers, and users.

WhatsApp us