The world of electronics is constantly evolving, with each technological leap requiring increasingly sophisticated components. Among these components, PCB gold fingers have emerged as essential connectors that enable high-performance devices. This article explores the world of gold fingers, delving into their functions, applications, and how they’re changing the way we interact with technology.

As a fast turnaround or quick-turn PCB Assembly Manufacturer /factory in Shenzhen China, FX PCB is able to fulfill orders in a fast delivery time with our modern technologies used in production.

Our factory carries out the assembly and installation of printed circuit boards to order. During the development and manufacturing process, constant quality control is carried out. We strictly follow your Gerber file and Bom list for your fast turnaround or quick turn PCBA projects, and we will also be glad to suggest you the alternative for your passive components to decrease your cost, but all replacement components need you to approve and make the final decision on whether you want to use them.

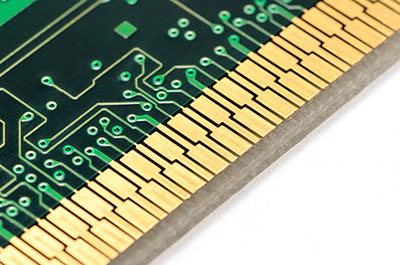

Gold fingers, often referred to as edge connectors, are a crucial but often overlooked component of modern electronics. These specialized connectors are typically found on the edge of a printed circuit board (PCB). What makes them stand out is their distinctive gold-plated contact surfaces. But what exactly are PCB gold fingers, and why are they essential?

Gold fingers serve as the bridge between the PCB and other electronic components, ensuring a reliable electrical connection. These connectors are called “PCB gold fingers” due to the thin layer of gold plating applied to their contact areas. This gold plating provides several key benefits, including resistance to corrosion and low contact resistance, making gold fingers an ideal choice for high-performance electronics.

Gold fingers play a pivotal role in connecting a PCB to various electronic devices, such as expansion cards, memory modules, or connectors. Let’s explore some of the primary ways gold fingers are utilized in the world of electronics:

Memory modules, such as RAM (Random Access Memory), are essential components in virtually all computing devices, from desktop computers to laptops and servers. Gold fingers on RAM modules serve a critical purpose: they allow these modules to establish a secure and high-speed connection with the motherboard.

The gold fingers on a RAM module align precisely with the corresponding slots on the motherboard, and when the module is inserted, the gold fingers make electrical contact with the motherboard’s connectors. This ensures a reliable data pathway for the rapid exchange of information between the RAM and the central processing unit (CPU).

The high-quality gold plating on these connectors contributes to low contact resistance, which is crucial for maintaining data transfer speeds and preventing signal degradation. As computer technology advances, faster and more efficient data transfer is paramount, making gold fingers an indispensable part of modern computing.

For gaming enthusiasts and professionals in graphic-intensive fields like 3D modeling and video editing, the role of pcb gold fingers in graphics cards cannot be overstated. Graphics cards, also known as GPUs (Graphics Processing Units), are responsible for rendering images and videos, often in real-time, at high resolutions and frame rates.

Gold fingers on graphics cards establish a high-speed data connection with the motherboard. The bandwidth and reliability of this connection are critical for smooth and responsive graphics rendering. Gamers, in particular, depend on the seamless operation of graphics cards to enjoy immersive gameplay experiences. Any interruption or data transfer issues would result in lag, stuttering, or even complete system crashes.

The gold plating on these connectors ensures that the electrical signals can be transmitted with minimal interference. Furthermore, the precise alignment of gold fingers with the motherboard’s connectors is vital to providing a stable connection, even during intense graphics processing.

Solid-State Drives (SSDs) and Hard Disk Drives (HDDs) are at the heart of data storage in modern computers and electronic devices. PCB Gold fingers on these storage devices enable them to interface efficiently with the motherboard, ensuring data is read and written at high speeds and with minimal latency.

For SSDs, gold fingers establish a connection to the motherboard that allows for the rapid transfer of data between the storage device and the CPU. The ability to read and write data quickly is essential for tasks like booting up an operating system, loading applications, and transferring files.

In the case of HDDs, pcb gold fingers perform a similar role. These connectors ensure that data is reliably transmitted between the spinning disks inside the HDD and the motherboard. The gold plating on the connectors helps reduce contact resistance, ensuring data transfer occurs smoothly and efficiently.

The expandability of a computer is a key aspect of its functionality. PCB gold fingers are also present on various expansion cards, such as sound cards, network cards, and other specialized hardware interfaces. These expansion cards allow users to customize and enhance their computing experience by adding specific features and functionalities.

Gold fingers on expansion cards establish connections with the motherboard that enable these cards to function seamlessly. Whether it’s a high-quality audio signal from a sound card or a high-speed network connection from a network card, these connectors ensure that data is transmitted reliably and without interference.

In the context of expansion cards, the precise alignment of PCB gold fingers with the motherboard connectors is crucial. Any misalignment or imperfect contact could result in data dropouts or poor performance. Gold fingers, with their high-quality plating, minimize such issues, contributing to the overall reliability of the expansion cards.

To meet the rigorous demands of modern electronics, gold fingers must adhere to specific specifications:

Gold fingers are typically constructed from a substrate material, most commonly FR4, and coated with a thin layer of gold. The thickness of the gold layer is typically measured in microns.

Precise dimensions of gold fingers are crucial. They must align accurately with corresponding connectors on other devices to ensure a reliable electrical connection.

The quality of the gold plating is a critical factor in the performance and longevity of gold fingers. High-quality plating minimizes the risk of oxidation and corrosion, ensuring a durable and dependable connection.

An essential design technique in the creation of pcb gold fingers is beveling. Beveling involves creating a slight angle at the edges of the gold fingers, rather than leaving them flat. This design approach offers several advantages:

Beveled gold fingers make it easier to insert and remove components, reducing wear and tear on both the PCB and the connectors. This is particularly beneficial for devices that may need to be upgraded or serviced.

The beveled edges reduce the chances of damage to the gold plating during insertion and removal of components, enhancing the longevity of the PCB and connected devices.

The beveled design minimizes signal distortion by ensuring a consistent and reliable connection between the PCB and other devices. This is crucial for maintaining the quality of data transfer and reducing potential data errors.

Gold fingers have a broad range of applications across various industries and products. Their unique properties and capabilities make them indispensable in a multitude of electronic devices:

Gold fingers are integral to the operation of smartphones, tablets, laptops, gaming consoles, and other consumer electronics. These connectors ensure smooth and reliable data connections, contributing to the overall user experience.

The aerospace industry relies on gold fingers in avionics systems, communication equipment, satellites, and other critical components. In aerospace applications, reliability is paramount, and gold fingers play a crucial role in ensuring data integrity.

Medical equipment, such as Magnetic Resonance Imaging (MRI) machines, patient monitoring devices, and diagnostic equipment, depend on gold fingers for precision and accuracy. These connectors are essential for reliable data transmission in the medical field.

In the automotive industry, gold fingers are found in control modules, infotainment systems, sensors, and various electronic components. They contribute to the safety, performance, and reliability of modern vehicles.

The unassuming gold fingers may appear as mere connectors, but their influence on the world of electronics and beyond is profound. Here’s how gold fingers are actively reshaping our world:

Gold fingers enable the development of smaller, more powerful electronic devices. The miniaturization of technology is evident in the smartphones, wearables, and IoT (Internet of Things) devices that continue to advance, making technology more accessible and integrated into our daily lives.

Gold fingers, with their high-quality connectors, support faster data transfer and increased storage capacity. This is fundamental to our ability to process and store information, from streaming high-definition videos to managing massive databases.

Gold fingers ensure the reliability of electronics in critical sectors such as healthcare, aerospace, and automotive. In these industries, the consequences of electronic failure can be severe.

Gold fingers play a pivotal role in maintaining consistent and dependable connections.

The gold used in gold fingers is highly recyclable. As the electronics industry increasingly focuses on sustainability and reducing electronic waste (e-waste), gold fingers play a role in promoting responsible practices.

In the rapidly advancing world of electronics, gold fingers are unsung heroes, connecting us to the technologies that shape our lives. These small, gold-plated connectors play a pivotal role in enabling faster, more reliable, and sustainable electronic systems. As technology continues to evolve, the impact of gold fingers on our daily lives and the broader world becomes increasingly evident, making them a vital component in the ever-changing landscape of innovation.

I am Peter Gong. I have been working in PCB and PCBA industry for 15+ years now. I have been a part of the PCB revolution with my dedication to circuit board technologies and creative ideas. I write in FX PCB to impart my knowledge on PCB and PCBA for all circuit board lovers, manufacturers, and users.

WhatsApp us