Ever wondered why your electronic device isn’t working as planned? The printed circuit board might be the culprit. PCB is the backbone that connects all components. And its quality can make or break your project. Picking the right PCB manufacturer offers multiple benefits. Top notch boards, timely delivery and fewer headaches.

With countless companies claiming to be the best, how do you find the one that truly fits your needs? This guide will show you how to choose a reliable PCB partner for stellar results.

Why the Right PCB Manufacturer Matters

Your PCB is the heart of your device. If it has problems, your whole project suffers. Bad quality PCBs cause delays and waste money. They can also hurt your brand’s reputation.

Choosing the right PCB maker means you get good boards that work well. You will get them on time and the maker will support you during the process. This saves you time, money and stress.

Here is What to Look for When Choosing a PCB Manufacturer

1. Quality and Certifications

Quality is the first thing to check. Good PCB makers follow strict rules to make sure their boards are perfect. They often have certificates like ISO 9001. This show that they meet high standards.

Ask if they test the PCBs. Good tests include checking the board’s electrical performance and looking for defects. The right PCB manufacturer will share these test results and explain them clearly.

2. Can They Make What You Need?

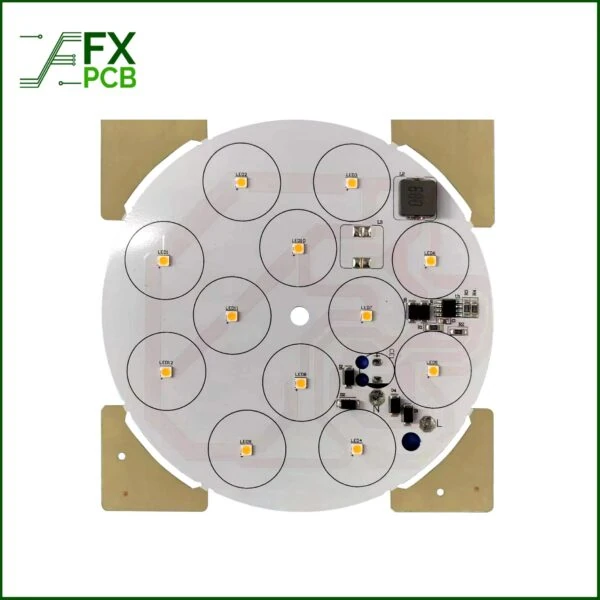

Not every manufacturer can make all types of PCBs. You need to know if they can make your specific board.

Do you need many layers? Flexible boards? Fast delivery? Or a small batch?

Check if the company can handle your requirements. If you have a special design, make sure they can produce it.

3. Experience and Reputation

Pick a company with experience. Experienced manufacturers know how to handle problems.

Check how long they have been in business. Look at reviews or ask for references. A company with many happy, long term customers is a good choice.

4. Technology and Equipment

Good manufacturers use modern machines and software. Ask if they have automated inspection tools or laser drilling.

The right PCB manufacturer uses new technology to reduce mistakes. This means better quality for your PCBs.

5. Price and Value

Price is important but don’t pick the cheapest option. Low prices can mean low quality or poor service.

Look for clear pricing. Ask what is included. Materials, tests, shipping.

Find a company that gives you the best value: good quality and service for a fair price.

6. Communication and Support

You want a manufacturer who answers quickly. Good communication helps avoid delays and mistakes.

Choose a company that answers your questions and keeps you updated.

How to Choose the Right PCB Manufacturer: Step by Step

Know Your Needs

Write down what you want. Include size, layers, quantity, delivery time and any special requests.

Clear needs help manufacturers give accurate quotes.

Find and List Manufacturers

Look online or ask for recommendations. Check their websites, reviews and certifications.

Make a list of companies that look promising.

Ask for Quotes

Send your PCB details to the companies. Compare prices, lead times and support.

Test With a Small Order

Order a small batch or prototype first. This shows if the manufacturer can deliver quality and meet deadlines.

Build a Partnership

If the test order is good, keep working with that manufacturer. Long-term partners give better prices and service.

Most Common Mistakes to Avoid When Choosing a PCB Manufacturer

Want to know what you should avoid? Here it is

- Choosing based on price only: The cheapest option may mean low quality or late delivery. Do not ever sacrifice quality for a low price.

- Ignoring experience: New or inexperienced manufacturers might not handle complex PCBs well. Check how long they’ve been in business.

- Skipping quality checks: Always ask about certifications like ISO 9001 and testing methods. Without this, you risk faulty PCBs.

- Poor communication: If the manufacturer is slow to reply or unclear, misunderstandings can happen. Test their response time before ordering.

- Skipping prototype orders: Don’t order a big batch without testing first. A small prototype helps you check quality and delivery times.

- Not asking for references: Check reviews or ask for past customer feedback to avoid surprises.

Avoid these mistakes to save time, money and stress in your project.

Benefits of a Good PCB Manufacturer

Working with a reliable PCB manufacturer brings many benefits. It helps your project run smoothly and saves time and money.

- Good quality boards

A trusted manufacturer gives you high-quality PCBs that work well and last longer. - Helpful support

You get clear answers, technical help, and updates throughout the process. This reduces stress and confusion. - On-time delivery

Your boards arrive when promised, so your project stays on schedule. - Long-term partnership

A good manufacturer becomes a trusted partner. You get better service, faster response, and possible discounts on future orders.

Choosing the right partner from the start helps you avoid any sort of problems later. It’s not just about buying PCBs, it’s about building a strong, reliable relationship.

Why FX PCB Is the Right Choice for You

FX PCB has over 10 years of experience making awesome circuit boards for customers everywhere. Our skilled team uses the latest tech in our ISO certified factory to deliver fast, high quality boards. We focus on getting it right and on time. This is the reason that so many customers stick with us for their projects.

Choose FX PCB and you will have a partner who’s all about your success. Ready to get started? Contact FX PCB today for boards that fit your needs perfectly!

Also Read: What is the Difference Between Rigid, Flex, and Rigid-Flex PCBs?

Frequently Asked Questions

What makes a PCB manufacturer the best choice?

High quality, experience, good communication, and meeting your project’s needs.

Why are certifications important for PCB makers?

They show the manufacturer meets tough quality and safety rules.

Can I order a small batch or test board first?

Yes. We also offer small or prototype orders to check quality and service.

How long it take to make a PCB?

It depends but usually a few days to a few weeks.

What should I ask before picking a PCB manufacturer?

Ask about quality checks, delivery time, cost, certifications and customer feedback.

Why does communication matter in PCB making?

Clear talks ensure your needs are met and avoid costly errors.