LED or Light Emitting Diodes have brought revolutionary changes in the lighting industry with a variety of lights. Also, it has reduced electricity bills quite unthinkably. But have you ever thought about how did LEDs make it possible?

LED uses the most updated circuit board formation that has enabled it to deliver such outstanding performance. However, you will need to find the best LED lighting circuit boards company, if you want the best LED lighting in your devices and other applications.

Various manufacturers develop LED circuit boards to meet the requirements of this ever-growing industry. Hence, selecting the best companies among them may be a tough task for you.

But, don’t worry. Or the article will make it easy for you.

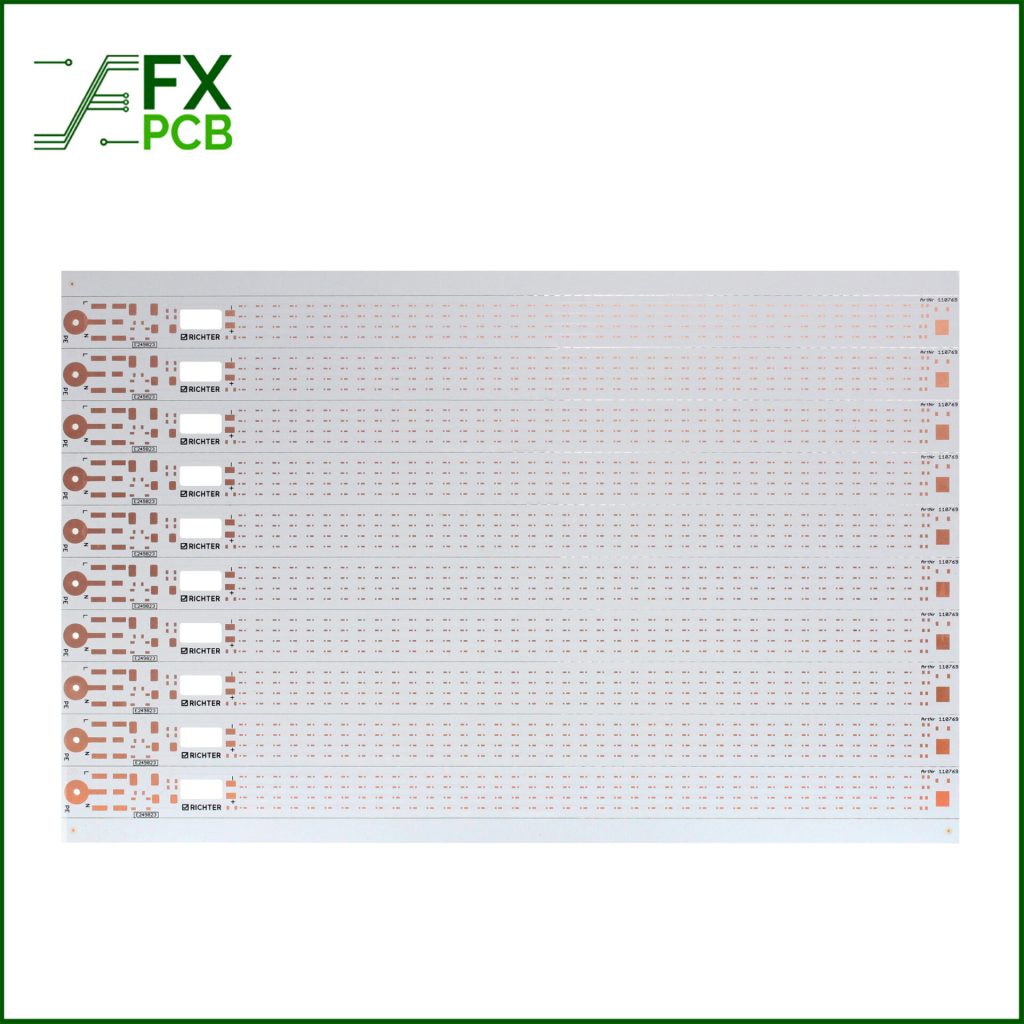

FX PCB is a professional manufacture for the LED PCB. we have Fr4, Aluminum ,Copper base and other materials for customer to choose, and we can give you the best suggestion and solution how to control your cost based on your requirements. Tell us your idea or send us your gerber file , we will reply you with the detailed quotation sheet or email.

LED PCB is one of the breakthroughs and latest technologies in the printed circuit board industry. Hence, we must understand the actual meaning of the LED PCB.

LED PCBs are not so cheap. Hence, you need to get a manufacturer who will at least keep the costing reasonable. Also, the manufacturer must have the flexibility to supply bulk or customized orders on time.

Since you came here we would expect that you understand LED circuit boards manufacturing and its applications. Yet, there’s no harm in describing it shortly to bring back the memories for a deeper understanding.

LED (Light Emitting Diode) refers to a solid-state lighting type. It uses a semiconductor to convert electricity into lighting sources. The LED will reduce the use of electricity by as much as 80% compared to the traditional light bulbs. This way it saves both your money and the environment.

Also, LED lights usually have a 25X longer lifespan than regular light bulbs. It is another extensive benefit of the LED lights.

But how does LED works so efficiently?

Well, printed circuit boards (PCBs) play the most crucial role behind such remarkable performance of the LED lights. The PCBs used in LED is mostly a thin board holding different electrical components and is made of fiberglass, ceramic, metal or other elements. It not only holds the essential electrical components but also uses a substrate to dissipate the heat from the components and offers protection.

The circuit board used in LED lighting is available in various formats depending on its different applications. But its basic remains the same both in terms of construction and working criteria. It includes-

The LED circuit board may use different elements at its core or substrate depending on its various applications and requirements. The material used to develop the circuit board core will largely attribute and control its characteristics and ability.

The most common materials are-

Since metal core PCBs is the most common component of LED circuit boards and it uses mostly aluminum as its base, let’s check out its common features and advantages.

The aluminum-made core used in LED PCB uses aluminum alloy as its base. The alloy base is made using aluminum, silicon, and magnesium. Since it uses three various materials, you will get the advantages of all three elements in one circuit board used for LED lighting.

The aluminum LED circuit board is commonly made using the following layers-

The aluminum LED circuit board could be single-layer, double-layer, or multi-layer depending on its application and users’ requirements. The assembly process uses either thru-hole or surface-mounting assembly to manufacture the LED circuit boards.

LED PCB or circuit board definitely comes with multiple benefits. But you can avail and extract all of these core benefits only when you work with the leading LED lighting circuit board company. It allows you to take full advantage of the LED applications.

Since the lights built with LED technology are temperature and heat-sensitive, it often requires the most complex construction. Only an experienced and committed manufacturer may offer you such a complex design with minimum flaws. Also, the company must have world-class engineers, workers, and above all, the best equipment and material to manufacture such LED circuit boards of highcomplexity.

FX PCB with its 10+ years of experience in the PCB industry outsources the best PCB materials from the best suppliers. These elements are then tested in our laboratory to ensure maximum quality. Finally, it goes through our extensive and inclusive manufacturing process using the best PCB machinery. And before delivering it to our respected customers, we will check the quality of our produced LED lighting circuit boards in our laboratory again to ensure maximum durability and flawless operations.

FX-PCB is FDA-registered for quality maintenance. Also, you will get both fixed and customizable offers from us. Therefore, you can order either a bulk amount of LED light circuit boards or only a few hundred prototypes just to check our quality.

LED lights are the new-normal equipment. Hence, LED light producers are on the lookout for the best LED lighting circuit board company for their needs. Unfortunately, they’re only a LED PCB manufacturers who can meet the growing demands of the industry with high-quality, durable, and affordable LED circuit boards.

FX PCB is committed to bringing the best LED light circuit board manufacturing service to meet your needs and applications successfully. Our customizable offers will truly serve your needs and that too within an affordable pricing and flawless quality.

I am Peter Gong. I have been working in PCB and PCBA industry for 15+ years now. I have been a part of the PCB revolution with my dedication to circuit board technologies and creative ideas. I write in FX PCB to impart my knowledge on PCB and PCBA for all circuit board lovers, manufacturers, and users.

WhatsApp us