The Flexible Circuits (FPCB) or, most commonly known as flexible PCBs, are often a misleading term in the communication and electronics world. Although it is named as a flexible printed circuit, the FPCB differs in manufacturing, fabrication, design, and application from that of regular PSBs.

So, if you are considering working with the flex PCB, at first, you need to understand what is flexible PCB in reality. For our valued customers’ convenience, we are going to reveal the definition, fabrication, design, and common types of flexible PCBs with their usage in today’s episode on metal base PCB discussion.

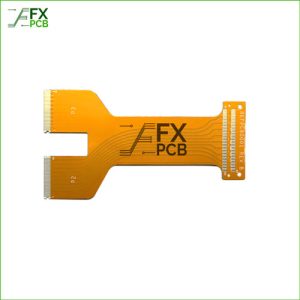

As the bane suggests, flexible PCBs are manufactured with materials that have the flexibility and stretching capacity, such as plastics. The flexibility comes handy when the PCB needs to shift or move without damaging the board components and connections.

The flexible PCB design is formed with the metal-clad foiling etching system. The manufacturers use copper as metal cladding.

Also, note that the components of flexible circuits may or may not come attached within the board (depends on the project needs). When the components come built-in attached, experts call it flexible electronic assemblies.

The flexible PCB has a wide variety (we will discuss them in the following parts), and their manufacturing technology varies accordingly. So, we are only profoundly going to discuss the standard Rigid-Flex PCB manufacturing procedure here.

The flex-rigid PCB is manufactured through the selective and sequential assembly of rigid and flexible PCB layers one after another. The flexible PCB materials are connected through plated holes. These plates are responsible for creating a successful connection between the different flex PCB layers.

At the upper head of the flexible PCB, you will see the rigid substrate material. It stays above the pre-peg content (often reinforced with resin).

Then there will be a thin covering film. Lastly, the leading flexible substrate material will be sandwiched between two layers of a rigid substrate, pre-peg resin, and covering film.

That’s how the manufacturers fabricate a useful, flexible PCB.

There are many types of flexible PCBs available in the market. Each can perform a myriad of electronics and intercommunication chores. The most common variations of flex PCBs are listed below.

Flexible circuit boards are highly optimized for advanced electronics and communication devices. The potential benefits include:

Flexible circuits have a variety of applications in different fields. There are hardly any modern-day electronics and commination areas where you won’t find the use of flex PCB or the updated long Flexible PCBs.

The flexible circuits have been developed to provide reliability, cost-saving, and long-lasting performances in the installed components. So, these days most electronics manufacturers opt for the PCB flexible circuits to offer sustainability to their products.

These are used widely in LCD televisions, cell phones, antennas, laptops, and what not! These communication devices have seen leaps development with the emergence of flex PCBs. However, the uses of the flex circuits are not limited here only.

You will also see it in hearing aids, advanced satellites, printers, cameras, and even in the calculators. Thus, you can ardently observe the use of the fantastic piece of circuit literally in every field in the modern era.

This is all about what is flexible PCB and its applications and types. We hope you now have an in-depth idea about the incredible circuit. You can use it literally for any applications in any field, and that what makes it stand out among all PCB types.

Since the modern electronics and communication world is highly dependent on it, FX PCB focuses on manufacturing and supplying the highest quality and cost-effective, flexible PCBs to the manufacturers.

I am Peter Gong. I have been working in PCB and PCBA industry for 15+ years now. I have been a part of the PCB revolution with my dedication to circuit board technologies and creative ideas. I write in FX PCB to impart my knowledge on PCB and PCBA for all circuit board lovers, manufacturers, and users.

WhatsApp us