Although the LED industry has developed tremendously, quick and effective heat dissipation of the LED boards has remained a concerning issue to most manufacturers. Since the LED board sees heat rise rapidly, it needs to be dissipated quickly to save the circuit board.

The application of metal core PCB has helped solve this LED issue to a great extent. However, not all metal core PCB manufacturers can provide you with high-quality, reliable, flawless, and durable metal core PCBs.

You need to look at a few factors of the manufacturer for metal core PCB to decide which supplier is going to meet the high-end requirements for the devices. Plus, you might be keen to learn the advantages and manufacturing process of metal core PCB briefly.

This write-up comes with the answer to all these super-important questions.

Metal core PCBs (MCPCBs) are circuit boards with a metal substrate layer that have superior thermal conductivity and are used in high-density circuits to dissipate heat quickly.

They have increased durability, use dielectric polymer layers and take less space on the board than traditional PCBs. They are more effective at dissipating heat than traditional PCBs.

MCPCBs, or metal core PCBs, are circuit boards with a metal substrate layer. Aluminum, copper, and steel alloy are the three most often utilized MCPCB metals.

The most economical PCBs are those made of aluminum; they are inexpensive and have superior thermal conductivity and capability.

A metal core printed circuit board is also referred to as MCPCB or thermal PCB. The name comes from its metal incorporated base. The metal base diverts and dissipates the heat generated in the circuit board quickly and fast to safeguard the electrical and electronic components.

The metal base actually diverts the excessive heat from the more important circuit board components to the less important areas on the same board. These areas include metallic core and heat sink backing locations mostly.

Hence, in short, the metal core PCB is used to manage the excessive heat generated in the circuit board components.

If it is a multilayer PCB, each layer will have an even distribution of the metalcore. For instance, in a 4-layer MCPCB, two layers will be on the top and the other two on the bottom of the metalcore. It will allow the metal core PCB to manage and dissipate the heat evenly and quickly. It protects the components and expands their lifespan.

Metal core PCB has several names in the industry-

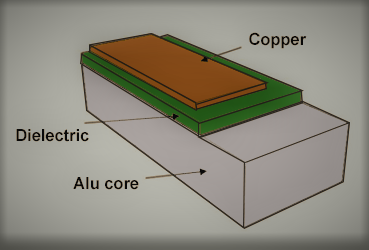

Metalcore PCB comprises different manufacturing stages. Its structure includes-

The copper layer varies from 1oz to 6oz, mostly. The metal layer is used as a heat spreader or sink. Depending on the number of layers the MCPCB has, the copper layer is adjusted to make space for the multiple layers.

If the LED MCPCB is single-sided the copper foil will attach to the dielectric material. It is thermally conductive to dissipate the heat quickly. Then another metal layer will attach with the existing dielectric layer. This metal layer can be-

The manufacturing tips of MCPCB includes the following suggestions-

The metal core PCB is a brilliant solution when it comes to cooling off multi-layer

You should already realize that manufacturing MCPCB isn’t an easy-going task. Hence, you must opt for the right metal core printed circuit board manufacturer. It will help you expand the lifespan and quality of your produced devices.

FX PCB promisesto offer the best budget-friendly metal core PCB schemes without any drop intheir quality and performance. Hence, you can expect the best MCPCB manufacturing with us.

The most practical benefits and advantages of MCPCB includes the following ones-

The applications of metal core PCB include-

Metal core PCBs have broughta revolution in the printed circuit board industry, especially, in LED devices. But for the best devices, you also need to opt for the right metal core PCB manufacturer. You can rely on FX PCB to get your right and required MCPCB supplies.

Also, the metal core PCBs are highly dependable for heat-dissipating and heat management to prolong the lifespan of devices. So, it is the future of the PCB industry.

I am Peter Gong. I have been working in PCB and PCBA industry for 15+ years now. I have been a part of the PCB revolution with my dedication to circuit board technologies and creative ideas. I write in FX PCB to impart my knowledge on PCB and PCBA for all circuit board lovers, manufacturers, and users.

WhatsApp us