Printed Circuit Boards (PCBs) are the heart and soul of modern electronic devices. They serve as the backbone, connecting various components and enabling the flow of electrical signals. The way components are attached to PCBs is a critical aspect of electronic design and manufacturing. This article explores the world of PCB mounting, with a specific focus on PCB mount switches.

The modern-day electronics world depends heavily on the Printed Circuit Boards (PCBs) as its backbone. A PCB is a medium to transfer the current through its copper pathway and it dissipates the heat to keep the tiny yet highlycomplex electronic equipment on it in perfect condition.

If you are to get the best PCBA and PCB for your digital devices, you have to know this PCB assembly process thoroughly. FX PCB with its years of experience understands this need and thus, we present you the detailed guideline.

FX PCB dont follow the standerd manufacturing process is no exception to it. Our process includes solder pasting on the PCB base, placing the electronic components in the right place, soldering them with the PCB, checking the accuracy, final inspection, and delivery to customers.

PCB mounting refers to the process of attaching electronic components to a printed circuit board. This process is essential in the manufacturing of electronic devices, as it determines the functionality, reliability, and overall performance of the product.

The way components are mounted on a PCB can significantly impact the product’s functionality and durability. Proper mounting ensures:

Electrical Connectivity: Components need to be securely attached to establish electrical connections.

Mechanical Stability: Mounting keeps components in place, preventing vibrations or movement.

Thermal Management: Efficient mounting aids in heat dissipation, crucial for component longevity.

Space Optimization: Effective mounting allows for compact and efficient PCB layouts.

Surface mount technology is a widely used method in PCB assembly. Components, like resistors, capacitors, and ICs, are soldered directly onto the PCB’s surface. SMT allows for compact designs and automated assembly, making it suitable for high-volume production.

Through-hole technology involves inserting component leads through holes in the PCB and soldering them on the opposite side. This method is known for its durability and suitability for components requiring high mechanical strength. However, it’s less space-efficient than SMT.

PCB mount switches are a specific category of components designed for easy attachment to PCBs. These switches serve various functions, from power on/off to user interface controls. Let’s delve deeper into PCB mount switches.

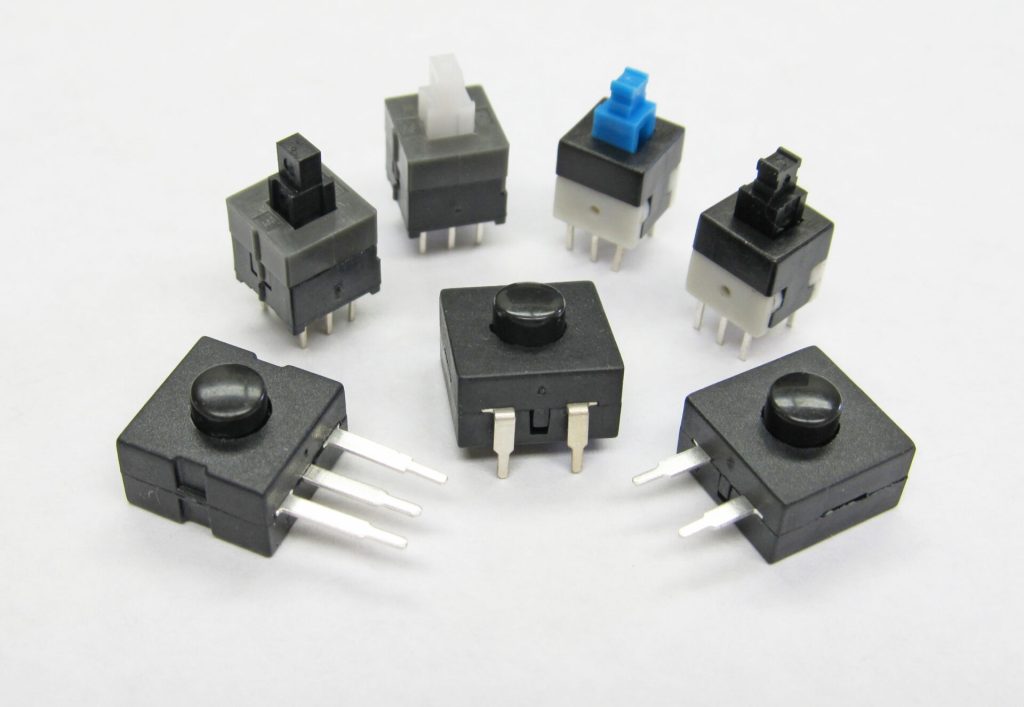

PCB mount switches, also known as PCB mounted switches, are specialized switches designed for easy integration into printed circuit boards. They come in various types, including:

Tactile Switches:

These switches provide tactile feedback when pressed, commonly used in keyboards and remote controls.

Push Button Switches:

Push buttons are commonly used for power on/off and mode selection in many electronic devices.

Slide Switches:

Slide switches are often used for basic on/off functions.

Toggle Switches:

Toggle switches are commonly found in devices with multiple operational states.

DIP Switches:

Dual in-line package switches allow users to configure settings by adjusting the switch positions.

Compact Design: PCB mount switches are designed to take up minimal space on the PCB.

Ease of Assembly: They are designed for easy soldering onto the PCB during assembly.

Reliability: When properly mounted, these switches offer high reliability and longevity.

Customization: PCB mount switches come in various sizes, shapes, and configurations to meet specific design requirements.

Mounting PCB switches involves the following steps:

Positioning: Determine the exact placement of the switch on the PCB layout.

Soldering: Securely solder the switch terminals to the PCB pads.

Testing: Verify the switch’s functionality to ensure proper electrical connectivity.

Section 4: Common Applications

Consumer Electronics

TV Remotes: Tactile switches are used for button presses.

Game Controllers: PCB switches facilitate user inputs.

Home Appliances: Power on/off switches are often PCB mounted.

Industrial Control Systems

Machine Controls: Toggle switches are used for equipment control.

Instrumentation Panels: PCB switches configure instrument settings.

Automotive Electronics

Dashboard Controls: Many vehicle functions are controlled by PCB mount switches.

Selecting the appropriate PCB mount switch for your application is crucial. Consider factors like:

Functionality: Ensure the switch type suits your device’s needs.

Durability: For high-use scenarios, opt for switches designed for millions of actuations.

Size and Form Factor: Choose a switch that fits within your PCB layout.

Environmental Conditions: Some switches are rated for specific environmental conditions like dust or moisture.

PCB mounting is a fundamental process in electronic design and manufacturing, and PCB mount switches play a vital role in this process. The right choice of PCB switches ensures not only the functionality but also the reliability and longevity of electronic devices. As technology continues to advance, the importance of proper PCB mounting and the versatility of PCB mount switches will only grow, making them a cornerstone of the electronics industry.

I am Peter Gong. I have been working in PCB and PCBA industry for 15+ years now. I have been a part of the PCB revolution with my dedication to circuit board technologies and creative ideas. I write in FX PCB to impart my knowledge on PCB and PCBA for all circuit board lovers, manufacturers, and users.

WhatsApp us