Why do some electronic devices perform reliably for years, while others break down within months? The answer often lies in one key process—Functional Testing. It’s not just a checkbox in the production cycle; it’s the backbone of Reliable PCBA (Printed Circuit Board Assembly). In today’s world of high speed manufacturing and rising customer expectations, even a small fault in a circuit board can lead to product recalls, brand damage and loss of trust. That’s why Functional Testing isn’t optional but it’s essential.

In this blog, let’s explore why Functional Testing is a crucial part of the assembly process and how it ensures the performance, safety and PCBA reliability your customers demand.

What Is Functional Testing in PCBA?

Functional Testing is the process of verifying whether an assembled PCB works as intended in a real-world environment. Instead of just checking for shorts or soldering issues, this test checks the final functionality of the board.

In simpler terms, it’s like a “final exam” for your circuit board. It is done before it leaves the factory. Test engineers simulate the actual working conditions and see how the board performs. This includes checking power supply behavior, digital and analog input/output signals, communication ports, sensors and more.

It goes beyond basic Printed Circuit Board Assembly Testing. While visual inspections and in-circuit testing catch many defects, they don’t confirm if the board functions as it should in the final product. Functional Testing does that and more.

The Role of Functional Testing in Ensuring Reliable PCBA

1. Final Verification Before Product Integration

Imagine spending weeks or months designing a device, only to find out after production that the core board does not perform its job. That is a nightmare you do not want to face. Functional Testing ensures that each unit meets your product’s actual performance requirements.

Be it for a consumer gadget, medical device or industrial control system, Functional Test for PCBA confirms the board is truly ready to be integrated into the final product. This level of testing is a safeguard against customer complaints and technical failures.

2. Enhancing Product Quality and Life

Functional Testing directly affects PCBA reliability. A board that performs well in tests under real conditions is more likely to last longer and perform better. This reduces field returns, warranty claims and costly rework.

In industries where long term performance matters like aerospace, automotive and healthcare, Functional Testing becomes even more critical. It’s not just about working once; it’s about working every time.

Why Functional Testing Stands Out in PCBA Testing

There are several kinds of PCBA Testing methods. Visual inspection, AOI, ICT and Functional Testing. Each has its place but Functional Testing is the only method that gives you a true picture of how the PCB will behave in the field.

Key Benefits of Functional Testing:

- Identifies hidden defects: Solder bridges, timing issues or poor firmware programming can go unnoticed in other tests but are caught in functional testing.

- Improves customer satisfaction: A tested and verified board gives end users peace of mind.

- Prevents financial loss: It’s cheaper to catch a problem on the factory floor than to fix it after a product ships.

- Supports complex product builds: If your board has multiple microcontrollers, sensors, or communication systems, functional tests are essential.

How Functional Testing Works in Practice

Test Fixtures and Custom Test Software

Functional Testing uses test fixtures and software that simulate the final product’s operation. Engineers apply voltages, simulate signals and monitor outputs using specialized tools. If something fails the system logs the error and the board is flagged for review.

Data Collection and Feedback Loop

Modern testing systems collect data that can be analyzed for trends. Are certain components failing more often? Is there a production batch with abnormal failure rates? This information feeds back into the manufacturing process making future boards more reliable.

Printed Circuit Board Assembly Testing vs Functional Testing

It’s important to differentiate between Printed Circuit Board Assembly Testing methods:

| Test Type | What It Checks | Limitations |

| Visual Inspection | Obvious physical defects | Can miss internal faults |

| AOI | Soldering, alignment | Doesn’t check actual performance |

| ICT | Electrical paths, component values | Doesn’t verify working logic |

| Functional Testing | Real-world operation | Requires more setup |

While all tests are valuable, Functional Testing is the only method that verifies actual behavior and ensures a Reliable PCBA.

When Should You Perform Functional Testing?

You should conduct Functional Testing after assembly is complete and any initial inspections or in-circuit tests have been performed. It’s the last checkpoint before shipping out the product.

For mission-critical industries or high volume production, it’s wise to incorporate Functional Testing as a standard process, not a luxury.

What Makes a Good Functional Test?

1. Customized to Product Needs

No two products are alike. Functional tests should be tailored to the specific functions your PCB must perform. Same test won’t catch every issue.

2. Fast and Repeatable

Testing shouldn’t slow down your production line. Modern test setups are designed to be fast and repeatable ensuring consistency across batches.

3. Integrated with Quality Systems

A good test system logs results automatically and integrates with your factory’s quality management systems. This helps trace faults and improve overall PCBA reliability.

The Cost of Skipping Functional Testing

Skipping or underestimating Functional Testing can lead to:

- Product failures in the market

- Costly recalls

- Lost customer trust

- Damage to your brand

In contrast, investing in functional tests may add time and cost upfront but it saves far more in the long run. It protects your reputation as well as it ensures your products live up to your promise of quality.

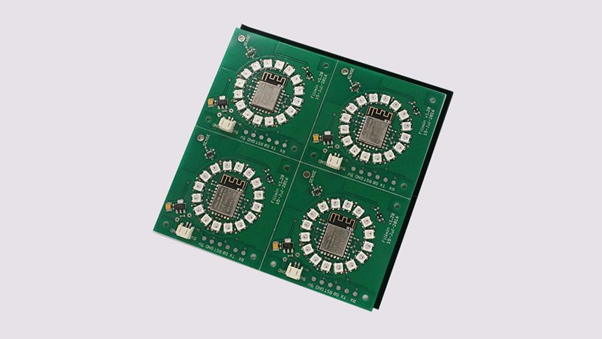

Functional Testing at FX PCB: Your Trusted PCBA Partner

At FX PCB, we understand the importance of Functional Testing in building reliable and long-lasting products. With over 10 years of experience, we’ve seen firsthand how thorough testing improves performance and customer satisfaction.

We don’t just build your boards. We test them to the highest standards. Our skilled team uses advanced tools to carry out detailed Functional Test for PCBA so that your boards perform perfectly, every time.

Whether you need high-speed boards, complex multi-layer PCBs, or IoT-ready assemblies, we’ve got you covered with complete PCBA Testing services, including functional verification.

To Finish

In today’s competitive electronics market, quality is not optional. It’s a requirement. Functional Testing is a very important step in delivering a Reliable PCBA that works as expected in real life applications. It reduces risk, enhances product performance and boosts brand credibility.

Don’t compromise on the last mile of your production process. Make Functional Testing a non-negotiable part of your PCBA workflow and partner with a manufacturer who treats it as seriously as you do.

Need functional testing for your next PCBA project? Let FX PCB handle it with care and precision. Contact us today and experience the FX PCB difference.

Also Read: How to Choose the Right PCB Manufacturer for Your Project